My 2018 ms462 died exactly a year and 2 days ago.

The decompression valve came flying out on a frosty morning while the saw was cutting big ash.

Since the evening of that day the saw has been sitting in my friends shed. He's a man in his mid 70s. A very eccentric fellow who is a trained heavy diesel mechanic and a more than competent small engine mechanic. In fact, he was the original mechanic at the local stihl dealership, he helped them set up their business and worked there for 25 years before retiring.

I want to get my saw back running, I've waited for him to fix it for over a year now so at this stage I'm just going to do it myself.

Our original plan was to heli coil it, which I have little orno faith in. Time certs are another thing I've heard of but don't know what it is.

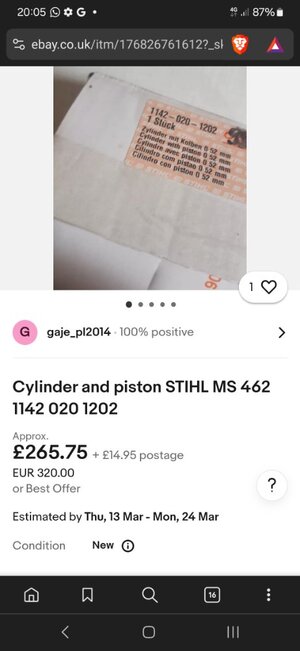

Really and truly the best option is a new top end. I can get one from Poland for 350 ish or from Greece for a bit more. There's no point trying any of the dealerships here, it will take them months to get it (if they even remember to order it at all) and then they'll charge an arm and a leg for it.

If I'm not mistaken didn't stihl change the 462 a bit some time ago? Will a new top end fit my 2018 saw? This is the one I'm looking at but there are others available.

View attachment 452962