You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TORQUE!

- Thread starter NightRogue

- Start date

Torque is a power measurement. Power is work over time. Work is force over distance. Without distance the force is irrelevant to work. Work cannot be stored. Stored kinetic energy is not torque. changing the flywheel, the power train etc. has no effect on the torque the motor produces. An efficient powertrain may deliver more torque to the ground by consuming less or allowing the motor to produce more HP by being at the proper RPM.

NightRogue

Pinnacle OPE Member

My terms may have been layman but you guys are right by correcting me, that mass increase will not change torque but widen the power band with acceleration sacrificed?

Am i right?

Am i right?

- Local time

- 6:04 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,280

- Reaction score

- 148,845

- Location

- East Jordan, MI

Yep, I believe you’re close. What you actually feel as torque is being produced by the motor, as the fly wheel and crank in a chainsaw aren’t heavy enough or of a large enough diameter to store any real measurable kinetic energy for a sustained amount of time, such as powering through a 20” tree. In order to feel something like that, you would need a momentum wheel. Something 2 to 3 feet in diameter that had mass at least around the perimeterMy terms may have been layman but you guys are right by correcting me, that mass increase will not change torque but widen the power band with acceleration sacrificed?

Am i right?

Sawrain

Pinnacle OPE Member

- Local time

- 9:04 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

In incredibly broad stroke terms short wide boars build RPMs and horsepower. Longer strokes with narrower boars create torque. makes a ton of sense when you think about how fast the piston has to move at the same rpm in each engine to cover the different distances and how much more room for error you have in building compression and using your expanded gases on the long stroke.

Simply adding weight to the rotating mass cannot and will not by definition add torque. Torque = (RPM/5250)/HP

Horsepower is a well.... power measurement. Power is work over time or the transfer of energy. The work being done in your engine is the expanding gasses pushing on the piston. This is unaffected by mass of the rotating assembly at any fixed RPM.

What additional rotating mass does do is store energy. The motor revs up slower as energy is stored as kinetic energy and loses RPM more slowly as the stored kinetic energy is released to maintain RPM but no additional power is created short of more rpm due to better balance.

So no greater mass does not add torque. It does add a torquey feel as it takes more to slow the saw down once it's going.

Good explanation, but both short and long stroke engines can make similar amounts of torque, for same size engines.

High torque engines don’t have to be long stroke.

Adding rotating mass doesn’t increase power or torque in any way.

But it can feel like it does, and if it smooths out the motor so it can turn more RPM it could add more HP.

I don't think added rotating mass will have that effect, if it has enough stored energy to get the piston past TDC each time at idle RPM then it's job done, no benefits to power production beyond that.

I do agree that more flywheel weight can make the saw more forgiving, in that it is less likely to bog when cutting/lightly pinched, the rotating/reciprocating mass plays a part here because most saws don't really have large amounts more torque to give than they already are when wot at max revs.

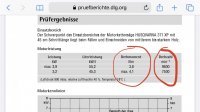

The usable part of a chainsaws powerband has a fairly flat torque curve, below is a husky 365.

Imagine you are sawing at 9300rpm and the bar pinches a little, the rpm drops, the drop in rpm causes the saw to operate in a "torquier" area, helping keep things going, but in this example torque only increased from 3.6 to 3.9Nm, or basically it can pull the chain with 8% more force, not much really, if you like to saw with the motor loaded at slightly below peak power rpm then you are probably down to only having 5% more torque available, for variations in cutting conditions the stored energy of the rotating mass helps us out in slowing down rpm changes, giving us time to respond by adjusting bar pressure, the kinetic energy isn't enough to do much meaningful work itself, just to give us time to respond, how much time? probably very little in Reality.

I know you all know this, but figured it was worth highlighting that the motor itself does not build much more torque as it is loaded down to lower rpms.

When talking about coming from being WOT and max RPM the following engine would "feel" torquey, as it build as much as 40% higher torque when "bogged down" from peak power/rpm to peak torque, yes I know it's a truck engine, but it is just to highlight an engine that is able to build a lot of torque in percentage terms as it is loaded, an engine capable of keeping on when the load on it is increased.

Flywheel size and weight also affects torque. Bigger/heavier flywheel doesn’t slow as quickly when saw bogs down in cut. Tractor like power. Lighter/smaller flywheel more responsive, revs faster. More topend power.

Lighter flywheels will be more responsive, but it will not rev faster and will not have more top end power.

Especially when you are in a big cut operating at a steady rpm, as if you are holding a constant rpm then within reason the flywheel weight is for that portion of the cut irrelevant.

The engine’s ability to create constant torque is what is desirable, and the rate at which it is produced is horsepower.

Torque is force, force does work, work combined with the element of time is power.

In a nutshell, the rotating mass does nothing but smooth out the Powerstroke’s force over a complete rotation. It does not add torque or horsepower, only carries energy via inertia.

Force alone is not work, (you didn't say it was either, but I just wanted to clarify.)

Force * distance is Work.

Force * velocity is Power, because velocity brings the time component.

Due to most modern saws operating at similar rpm ranges torque comparisons are fair, but also a little irrelevant, as it is the width and shape of the torque curve that is more important.

If two engines exist making 5hp at 6000rpm (6Nm torque) and 12000rpm (3Nm torque) and a sprocket exists to have matching chain speeds, then two engines would apply the same force and speed to the chain.

HP is the work you can achieve in a time frame, it can't tell you the engines characteristics, but it can tell you performance, you can't really be tricked here.

Torque is force in this scenario, and the reality is that it's raw number does not carry that much weight, if an engine has 6Nm but can only supply it at 3000rpm it's not useful here.

Horsepower is king, not torque. but it is necessary to have a wide friendly power band.

And back to where we started, an engine's operating characteristics are much more determined by overall design than just long/short stroke, for a type of engine torque/litre is normally fairly consistent, probably 50 to 70 Nm/litre for chainsaws.

Torque/litre normally somewhat correlates with volumetric efficiency, which between pro saws is probably similar, as such I would imagine specific torque outputs, with displacement accounted for would be not too different between many short and long stroke saws.

Edit: lastly, high horsepower slower revving saws such as the 090 & Cs1201 have to have large amounts of torque, as in mathematically, you can look at it as a feature or as just the amount of torque needed to achieve the horsepower at the operating rpms designed for.

Last edited:

Wonkydonkey

Plastic member

- Local time

- 11:04 PM

- User ID

- 3189

- Joined

- May 14, 2017

- Messages

- 5,373

- Reaction score

- 24,676

- Location

- Sussex, UK.

This good thread just got me back into reading the Gordon Jennings book,

Two-strokes Tuners Handbook

Two-strokes Tuners Handbook

- Local time

- 6:04 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,339

- Location

- Strong Island NY

Added weight does nothing except momentarily convert kinetic energy to potential energy when a load is placed.

The only time I’d ever want a heavier crank would be if it was to strengthen the crank/take up case volume/balance out a heavier piston. I’d take lighter anyday.

The only time I’d ever want a heavier crank would be if it was to strengthen the crank/take up case volume/balance out a heavier piston. I’d take lighter anyday.

Sawrain

Pinnacle OPE Member

- Local time

- 9:04 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

Torque is a power measurement,

I wouldn’t really say that, It has no time or displacement.

Work cannot be stored

I wouldn’t say that either, when the flywheel and crankshaft are accelerated to 10,000rpm work is done on them to achieve this, while completing the cut at 10k rpm the amount of energy contained within the flywheel/crank (stored) is equal to work done to accelerate them, and it remains that way until the saw decelerates.

Stored kinetic energy is not torque.

In our case it kind of is, or at least will be, it takes torque from the engine to accelerate the flywheel, and when the chainsaw is slowing down it will give up its stored energy up as a torque.

What other way can the bulk of the stored kinetic energy be given up as, outside of heat, noise, windage and cooling air?

I agree 100% but as an academic discussion the flywheel does absorb energy when being accelerated, that is released when decelerated, that can cause an effective positive spike in torque when slowed rapidly, which of course has to be repaid as the rpms are rebuilt.changing the flywheel, the power train etc. has no effect on the torque the motor produces

Though sawing being effectively a constant rpm task, once in the cut really does make this just for academic discussion, it’s not like a car/bike where The flywheel is eating precious power as you accelerate every time, the time when you want your torque/power the most.

And the more I think about it, I feel the weight of the flywheel in our case does very little, I mean turn the ignition off in a cut, the stored energy won’t get you far at all, a near instance stop.

Last edited:

- Local time

- 6:04 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,339

- Location

- Strong Island NY

Agreed ^^^

I have a heavier than normal billet flywheel on my 406 SBC. The added weight keeps inertia going so that I can idle at 600 rpm with a .600 lift flat tappet cam. With the lighter flywheel I’d have to be 800-900 to keep it idling.

A heavier flywheel has its place, a saw just isn’t one of them IMHO.

I have a heavier than normal billet flywheel on my 406 SBC. The added weight keeps inertia going so that I can idle at 600 rpm with a .600 lift flat tappet cam. With the lighter flywheel I’d have to be 800-900 to keep it idling.

A heavier flywheel has its place, a saw just isn’t one of them IMHO.

huskyboy

Sorta a husqvarna guy...

- Local time

- 6:04 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,025

- Reaction score

- 43,483

- Location

- Ct

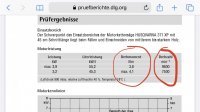

If one observes the KWF test between the 2171 and 371xp, it is interesting to note the difference in what rpm they make max torque at... the 2171 makes it at a slightly lower rpm (more of it as well) and 371 makes it at a slightly higher rpm. The only real difference between these two saws is the flywheel, carb and piston. The 2171 has a heavier 2 ring piston and heavier 14 fin flywheel. Same cylinder as a 371. Now what does this mean? I don’t know, and the difference is minor. But it is there. 371xp

371xp 2171

2171

371xp

371xp 2171

2171Sawrain

Pinnacle OPE Member

- Local time

- 9:04 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

Agreed ^^^

I have a heavier than normal billet flywheel on my 406 SBC. The added weight keeps inertia going so that I can idle at 600 rpm with a .600 lift flat tappet cam. With the lighter flywheel I’d have to be 800-900 to keep it idling.

A heavier flywheel has its place, a saw just isn’t one of them IMHO.

Agreed, and is it bad to quote yourself?

if it has enough stored energy to get the piston past TDC each time at idle RPM then it's job done, no benefits to power production beyond that.

I used way too many words to say chainsaw flywheels are predominantly for allowing the saw to idle, run the ignition and provide cooling air.

Not much difference between the 066 original and poly flywheel in practice.

Deets066

AKA Deetsey

- Local time

- 6:04 PM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,583

- Location

- Illinois

So, the port timing and ignition timing is identical?If one observes the KWF test between the 2171 and 371xp, it is interesting to note the difference in what rpm they make max torque at... the 2171 makes it at a slightly lower rpm (more of it as well) and 371 makes it at a slightly higher rpm. The only real difference between these two saws is the flywheel, carb and piston. The 2171 has a heavier 2 ring piston and heavier 14 fin flywheel. Same cylinder as a 371. Now what does this mean? I don’t know, and the difference is minor. But it is there.View attachment 228362371xpView attachment 2283632171

Sawrain

Pinnacle OPE Member

- Local time

- 9:04 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

If one observes the KWF test between the 2171 and 371xp, it is interesting to note the difference in what rpm they make max torque at... the 2171 makes it at a slightly lower rpm (more of it as well) and 371 makes it at a slightly higher rpm. The only real difference between these two saws is the flywheel, carb and piston. The 2171 has a heavier 2 ring piston and heavier 14 fin flywheel. Same cylinder as a 371. Now what does this mean? I don’t know, and the difference is minor. But it is there.View attachment 228362371xpView attachment 2283632171

Interesting.

I wonder what ramp rate, or rate of change of rpm they use to test the saws is or steady state every 100rpm, probably not.

How many saws are tested of each model, more questions than answers here I think.

huskyboy

Sorta a husqvarna guy...

- Local time

- 6:04 PM

- User ID

- 1352

- Joined

- May 30, 2016

- Messages

- 10,025

- Reaction score

- 43,483

- Location

- Ct

I agree, my intentions wasn’t to say flywheel or piston/crank mass affects torque. Rather that it is interesting that there is a difference at all... whether that is related or not who knows.Interesting.

I wonder what ramp rate, or rate of change of rpm they use to test the saws is or steady state every 100rpm, probably not.

How many saws are tested of each model, more questions than answers here I think.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 26

- Views

- 5K