- Local time

- 7:01 AM

- User ID

- 26879

- Joined

- Jun 7, 2023

- Messages

- 1,755

- Reaction score

- 5,056

- Location

- Norcal

Probably wouldn't change the bearings, myself.

Can be made by many companies, depends on who gives them a deal i suppose. I’ve seen slacker, sks, skb and others in Stihl boxes before.I think Stihl proprietary bearings are made by F A G typically, fwiw.

Kinda different lookingI’ll post photos later but was trying to gauge the age of a Stihl bar I got on auction yesterday. White West Germany made bar with orange writing on it says rollomatic 6 on it and Stihl in bright stihl orange. 20” .404 with a 3002 mount on it.

Yes the reset procedure is 30-60 seconds in triangle then hold open and let it tune up and down. Here’s the two procedures and if it won’t run long enough to complete the reset odds are the solenoid kit will fix it. Other thing I had issue with was a plugged screen in carb on one.I have an MS362C in the shop, customer says it falls on its face under load.

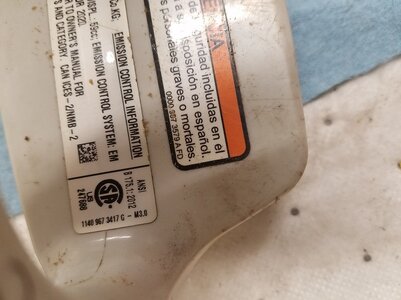

The label on the handle says it is version 3.0.

View attachment 472553

I when through the calibration procedure; 30+ seconds in triangle with the brake on, then release the brake and pin the throttle open. I could hear it hunting, rev up, back down, then it dies. I went through the process twice with the same results.

Fuel filter looks a little iffy.

View attachment 472554

I have the solenoid/filter kit 1140 007 1802, is it worth the effort and expense to change the filter and solenoid, or should I just tell this user to take it to a Stihl shop with the equipment to connect and see what's happening?

Mark

Yes it’s idle in triangle 45-90 seconds and shut off without touching throttle. Green is proper one for the old saws with black solenoid. Put new orange fuel filter in also if not already done.For the earlier versions of this saw do I follow the old procedure of a 90sec idle in "choke" like my 661?

Saw won't idle at a fast enough rpm to keep running. currently rebuilding the carb...kit on the way. It came with a black solenoid so I am assuming 1st iteration. I swapped in a green one, no change....hence, time to try a rebuild

I have never done the 3.0 reset with the brake on, probably not gonna make a difference, but worth a try....I when through the calibration procedure; 30+ seconds in triangle with the brake on, then release the brake and pin the throttle open. I could hear it hunting, rev up, back down, then it dies. I went through the process twice with the same results.

Can't do thatI have never done the 3.0 reset with the brake on, probably not gonna make a difference, but worth a try....

I have never done the 3.0 reset with the brake on, probably not gonna make a difference, but worth a try....

How the hell does that work hen the thing goes to high rpm’s?You have to have the brake on for the 3.0 calibration or it won't calibrate.

Above if you read, method one leaves the chain brake on and lets the saw idle for 90 seconds (without pinning it to high RPM). If you go with method 2, chain brake on for 30 seconds idle, then release chain brake and pin it to full throttle, as it goes through its calibration at some point it will drop in RPMs by itself, then you release the throttle, let it get to idle, set the brake and turn it off. I think that the calibration cycle needs the brake on to set its initial RMP threshold.How the hell does that work hen the thing goes to high rpm’s?

That makes sense. Full throttle with the brake engaged does not.Above if you read, method one leaves the chain brake on and lets the saw idle for 90 seconds (without pinning it to high RPM). If you go with method 2, chain brake on for 30 seconds idle, then release chain brake and pin it to full throttle, as it goes through its calibration at some point it will drop in RPMs by itself, then you release the throttle, let it get to idle, set the brake and turn it off. I think that the calibration cycle needs the brake on to set its initial RMP threshold.

I agree!Full throttle with the brake engaged does not.

How the hell does that work hen the thing goes to high rpm’s?

My goof...since I haven't had a gen3 to play with I knew zip on that procedure. I'd seen a couple youtube vids but it looked like the system did the rpm increase on its own...oops.Lol.

It doesn't go to high RPM's until you disengage it and squeeze the trigger.

Did you read what Chris posted above for the 2 separate calibration processes for the early and 3.0 models ?

Never been an issue on my 261 or my 661, have always calibrated with brake off... nor has it been an issue on the countless saws i did for customers in the stihl shops i worked at for the last 10 yrs....You have to have the brake on for the 3.0 calibration or it won't calibrate.

Never been an issue on my 261 or my 661, have always calibrated with brake off... nor has it been an issue on the countless saws i did for customers in the stihl shops i worked at for the last 10 yrs....

I am aware of that.... 2.0 did, and i never calibrated those with the brake on either.... never said it was specific to my 3.0 calibration... my 261 was a 2.0 when i got it.... have since changed the coil to a 3.0 coil out of a 362...still dont use the brake for calibrations... i see too many saws a year with melted brake housings to want to put any of that sort of heat into a saw.... it builds fast, and wears stuff out quick...M tron 3.0 didn't exist 10 years ago...