You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STIHL The Official Stihl Chainsaws Thread

- Thread starter Greenthorn

- Start date

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 6:19 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,788

- Location

- South Carolina

Congratulations on your score with the 066!

Lol you can tell what kind of people you're dealing with on here, when all of a sudden we become obsessed about the danm BAR NuTs Haha!

Lol you can tell what kind of people you're dealing with on here, when all of a sudden we become obsessed about the danm BAR NuTs Haha!

Al Smith

Here For The Long Haul!

- Local time

- 6:19 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,682

- Reaction score

- 14,926

- Location

- North western Ohio

The flange nuts have a little more surface area plus do less damage to the cover over time . I didn't have that many larger Stihl flange nuts but probably a hundred smaller headed M8 flange nuts .Those were OEM Ford that had resistance threads I ran a tap through before I retired .Cheap is good, free is better .

OGStihl

Well-Known OPE Member

Years ago I had a chance to buy a bunch of them years ago and I’ve used them ever since. Got a whole sack of them at a swap meet.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sawrain

Pinnacle OPE Member

- Local time

- 9:19 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

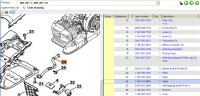

Any 090 experts in the house?

I was just test fitting some parts on a saw I pulled down a while ago, low on compression but running.

That’s when I noticed a miss match of parts in the wrist pin area, the older split/capped big end bearing 090 crankshafts have spacers to centre the con rod between the piston bosses.

This newer 090 didn’t have spacers, and they are not in the IPL, the IPL does show a wider little end bearing than I have, but that still would not centralise the connecting rod to the piston.

Below are the 2x spacers from an early 090.

Below an early 090 two piece con rod arrangement, spacers shown.

Below how my later 090 was.

Derp, answer is the newer connecting rod fits the piston correctly without spacers, but that my saw was fitted with the old style, and as such incorrect bearing.

Old bearing 16.5mm wide, new bearing 19.5mm wide.

I was just test fitting some parts on a saw I pulled down a while ago, low on compression but running.

That’s when I noticed a miss match of parts in the wrist pin area, the older split/capped big end bearing 090 crankshafts have spacers to centre the con rod between the piston bosses.

This newer 090 didn’t have spacers, and they are not in the IPL, the IPL does show a wider little end bearing than I have, but that still would not centralise the connecting rod to the piston.

Below are the 2x spacers from an early 090.

Below an early 090 two piece con rod arrangement, spacers shown.

Below how my later 090 was.

Derp, answer is the newer connecting rod fits the piston correctly without spacers, but that my saw was fitted with the old style, and as such incorrect bearing.

Old bearing 16.5mm wide, new bearing 19.5mm wide.

Last edited:

Nutball

Here For The Long Haul!

- Local time

- 5:19 PM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,846

- Location

- Mt. Juliet, TN

What does part 1145 141 8600 do? Fuel? Impulse? The saw shop ordered the wrong part. Everything is a "stihl hose" with no indication of what the hose does.

Last edited:

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 6:19 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

Ontario Firewood Resource

Super OPE Member

- Local time

- 6:19 PM

- User ID

- 15772

- Joined

- Feb 18, 2021

- Messages

- 128

- Reaction score

- 204

- Location

- Toronto, Ontario, Canada

Ya, never felt intimidated by 4 ft plus blocks. Sharp chain is the only thing you need to buck the big stuff.And they are an excellent saw overall

Ontario Firewood Resource

Super OPE Member

- Local time

- 6:19 PM

- User ID

- 15772

- Joined

- Feb 18, 2021

- Messages

- 128

- Reaction score

- 204

- Location

- Toronto, Ontario, Canada

Speaking of big stuff, this just in...

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 6:19 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

I'm in need of an 045/056 crank w/cam lobe for a points ignition 1115 saw. Part number is 1115 030 0400 and came both with and without the cam lobe and was also actually used in electronic ignition saws for a time. The serial# breakpoint for the non-points crank began with x 11 026 121. Any 045/056 prior to that serial should have the points crank.

Would consider a complete bottom end assembly with smooth big end rod bearing. A smooth PTO side bearing would obviously also be a plus.

TIA for any assistance.

Would consider a complete bottom end assembly with smooth big end rod bearing. A smooth PTO side bearing would obviously also be a plus.

TIA for any assistance.

rocketnorton

Pinnacle OPE Member

- Local time

- 3:19 PM

- User ID

- 638

- Joined

- Jan 21, 2016

- Messages

- 1,116

- Reaction score

- 4,011

- Location

- surrey, bc, can

have box of 045, roached piston

can look fer points lobe later

can look fer points lobe later

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 6:19 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

Much appreciated, Pete. Saw ya over in the Swap Meet, too. Thx.

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 6:19 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,788

- Location

- South Carolina

So right now I'm working on a 066 round top (poly flywheel)I found in the scrap yard before Christmas. It had a clutch/ oil pump explosion of some kind and a bad bearing pocket on that side plus the ear that holds the inside spike was broken.

The rest of the saw is salvageable ( one broken fin on the cylinder) . I ordered some plastics and a case from farmertech and put the crank in the freezer and heated up the flywheel side bearing with a heat gun, the crank dropped right in.

The flywheel side got about half way and hung tight so I gently centered a large washer and a socket on the bearing and confidently wacked it down with a hammer. It seems to be centered pretty good , the crank turns freely and it definitely has seal tension.

Without special tools does that sound about right?

The rest of the saw is salvageable ( one broken fin on the cylinder) . I ordered some plastics and a case from farmertech and put the crank in the freezer and heated up the flywheel side bearing with a heat gun, the crank dropped right in.

The flywheel side got about half way and hung tight so I gently centered a large washer and a socket on the bearing and confidently wacked it down with a hammer. It seems to be centered pretty good , the crank turns freely and it definitely has seal tension.

Without special tools does that sound about right?

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 6:19 PM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,957

- Reaction score

- 3,908

- Location

- Ohio

I've changed my method from the heated case / frozen bearing approach to just using a 1/2"~ 5/8" nut and bolt with washers to install bearings into case halves. Just secure the head of the bolt (with washer) by whatever means ( a vise is preferable if the case design allows) and use a nut and washer to draw the bearing into the case. There's equal pressure on both races and there will also normally be a positive stop when fully seated if the washer is just slightly smaller than the outer race. (This keeps the washer from stopping at the case if the bearing is supposed to be slightly recessed when bottomed out). Wish I would have run across this approach long ago.

As for installing cranks into case halves with bearings already installed, I just use extended length case bolts and slowly and uniformly draw the case together until the normal bolts will reach and finish up with those.

As for installing bearings onto cranks first, a cold crank and heated bearing work pretty well there. Heat the bearing in hot oil in a USC or on a hot plate and it should slide right on. No heavy heat with a gun or oven to possibly distort the cages. And here's one of the only places I'll use a hammer these days if the fit is stubborn even with the heat..., but only on the inner race with an appropriate sized socket. The other is to give each end of the crank a couple good whacks for centering once everything is buttoned up and ready for further assembly.

It's been my humbling experience that hammers at the wrong time in the wrong situation usually lead to more frustration than what made you reach for one in the first place!

As for installing cranks into case halves with bearings already installed, I just use extended length case bolts and slowly and uniformly draw the case together until the normal bolts will reach and finish up with those.

As for installing bearings onto cranks first, a cold crank and heated bearing work pretty well there. Heat the bearing in hot oil in a USC or on a hot plate and it should slide right on. No heavy heat with a gun or oven to possibly distort the cages. And here's one of the only places I'll use a hammer these days if the fit is stubborn even with the heat..., but only on the inner race with an appropriate sized socket. The other is to give each end of the crank a couple good whacks for centering once everything is buttoned up and ready for further assembly.

It's been my humbling experience that hammers at the wrong time in the wrong situation usually lead to more frustration than what made you reach for one in the first place!

Last edited:

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 6:19 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,788

- Location

- South Carolina

Its a tiny hammer , so I'd be a little frustrated. Lol

Similar threads

- Replies

- 49

- Views

- 1K