Max AKA Knightmax was asking about some oiler parts and sent me down a bit of a rabbit trail. In the end I concluded there were 4 different part numbers for the pulse pump (automatic oiler) on the large frame saws and in the end, they can all be used interchangeably.

60253, 67917, 83135, 89498

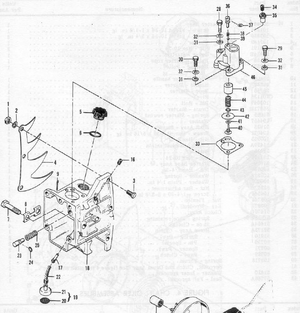

View attachment 405043

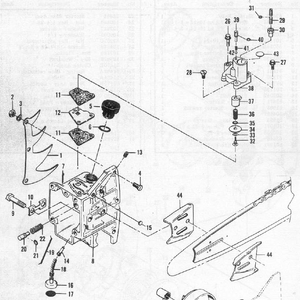

View attachment 405045

Aside from the pump body differences, the other variations were pretty minor, different adjuster screws, different part numbers for the sleeve and ring, and some mounting hardware differences. The only difference between 83135 and 89489 shown above are the adjuster screw and mounting hardware. I guess McCulloch was confused as well, as both of those came from factory packaging as 89489 yet one is painted and has a hex adjuster screw, the other is bare aluminum and has the set screw with lock nut.

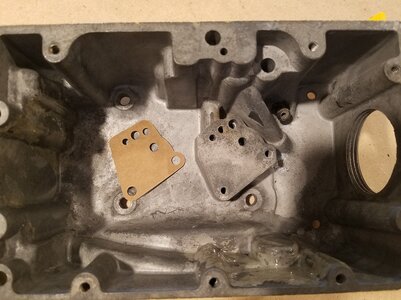

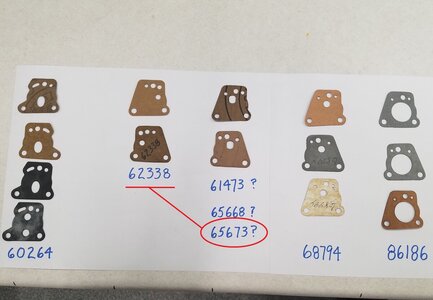

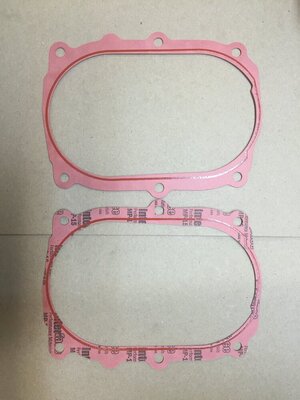

The investigation of the pumps led me to look through the gaskets I have and try to determine what is what. From the various IPL's I came up with a list of gasket numbers (60264, 61473, 62338, 65668, 65673, 68794, and 86186) and tried to then determine what I actually had.

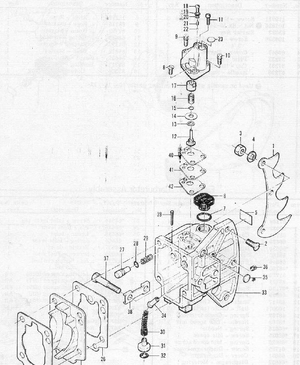

Here's a start:

View attachment 405046

As you may imagine, having parts come from multiple sources over 10 years or so, there was a lot of confusion on the real part numbers.

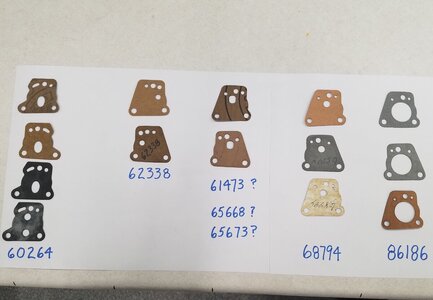

The same pumps are used on the later 450 and all 550 model front tank saws, but use a different gasket. With the gasket PN and a fuel tank to look at, I could determine that 62338 is in fact the only gasket that will work with either pump on those front tank saws.

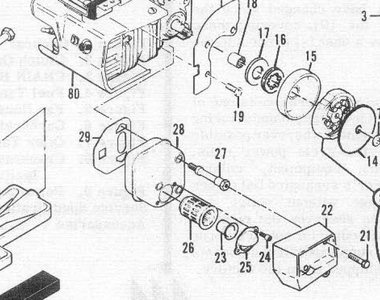

View attachment 405047

I also confirmed that all of the top tank saws have the same mount for the oil pump. Shown L-R the rigid saws, CP, and SP type oil tanks.

View attachment 405048

Mark