You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Metalworking Thread

- Thread starter davidwyby

- Start date

edisto

Super OPE Member

I Googled annealing, it is a similar process.

I will settle with both of us being right!

I haven't tempered at a fixed temperature, but I have applied heat to draw back a quenched part, which is a form of tempering. Heating it relatively gently will draw it back to blue, and then to a straw color. It's still hard, but not as brittle.

To work on a hardened part, I'll heat it red, and then let it cool, which anneals the metal, making it soft enough to work. After that process it would need to be heated red and quenched again.

My understanding (which might be way off) is that for tempering, the temperature of the metal never gets hot enough to make it red, but for annealing, it has to.

The former is a problem for me, because my brain doesn't seem to register metal as too hot to touch unless it is glowing...

edisto

Super OPE Member

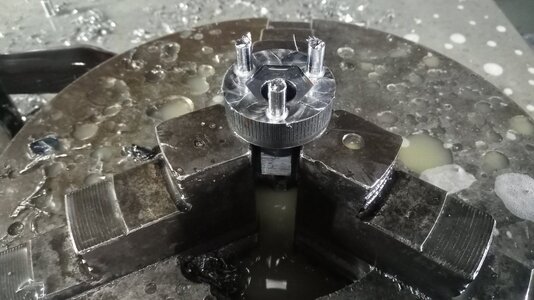

Dolmar 420/460/4k/5k/6100 clutch removal tool.

Impact drive proof!

That is some pretty work!

- Local time

- 9:52 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,882

- Reaction score

- 59,141

- Location

- Croatia

Thank You very much!That is some pretty work!

A fair amount of time, effort & $$$ went into making them.

I have made 5 different clutch removal tools, 3 for Husqvarna and 2 for Dolmar/Makita.

edisto

Super OPE Member

Thank You very much!

A fair amount of time, effort & $$$ went into making them.

I have made 5 different clutch removal tools, 3 for Husqvarna and 2 for Dolmar/Makita.

A much better result than the sockets that I have hacked up with my angle-grinder!

Yukon Stihl

Pinnacle OPE Member

- Local time

- 12:52 AM

- User ID

- 508

- Joined

- Jan 11, 2016

- Messages

- 1,316

- Reaction score

- 5,172

- Location

- Great White North

My version

Find an old socket with the right outside diameter weld on two or three rods of the right diameter

Find an old socket with the right outside diameter weld on two or three rods of the right diameter

- Local time

- 9:52 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,882

- Reaction score

- 59,141

- Location

- Croatia

Many ways to make a custom tool.My version

Find an old socket with the right outside diameter weld on two or three rods of the right diameter

If it works, it's good!

- Local time

- 2:52 AM

- User ID

- 1674

- Joined

- Aug 10, 2016

- Messages

- 1,475

- Reaction score

- 4,495

- Location

- Nebraska

I found one and ground out what was in the way. Maybe an IMPACT socket would work as well. That was for a 3 shoe. It hasn't broke 'cuz I bought one and use it now.My version

Find an old socket with the right outside diameter weld on two or three rods of the right diameter

- Local time

- 9:52 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,882

- Reaction score

- 59,141

- Location

- Croatia

Yukon Stihl

Pinnacle OPE Member

- Local time

- 12:52 AM

- User ID

- 508

- Joined

- Jan 11, 2016

- Messages

- 1,316

- Reaction score

- 5,172

- Location

- Great White North

Wish I had the tools and skilz to do stuff like that.My custom made ones are challenging Solid-Carbide end mills, and clamping vices.

View attachment 476421

I had to swap out the broken mill bit and redo this one.

- Local time

- 9:52 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,882

- Reaction score

- 59,141

- Location

- Croatia

It is fun to tinker up something of Your own.Wish I had the tools and skilz to do stuff like that.

And it feels very satisfying when it comes out the way You envisioned it.

- Local time

- 2:52 AM

- User ID

- 624

- Joined

- Jan 20, 2016

- Messages

- 7,793

- Reaction score

- 41,089

- Location

- NE OK

Same here...Wish I had the tools and skilz to do stuff like that.

Yukon Stihl

Pinnacle OPE Member

- Local time

- 12:52 AM

- User ID

- 508

- Joined

- Jan 11, 2016

- Messages

- 1,316

- Reaction score

- 5,172

- Location

- Great White North

- Local time

- 12:52 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,678

- Reaction score

- 38,415

- Location

- Extreme Southeast CA

- Local time

- 9:52 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,882

- Reaction score

- 59,141

- Location

- Croatia

This wasn't funny.It is fun to tinker up something of Your own.

And it feels very satisfying when it comes out the way You envisioned it.

Called it quits after the fourth 7.0mm end mill committed suicide.

It is a proven milling program, I used it over a dozen times with no issues regarding tooling choice, feeds & speeds.

Come to think of it, maybe I had a bad collet causing out of round.

P.S./Edit:

A 10.0mm end mill processed the top & ID, no issues.

Last edited:

- Local time

- 12:52 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,678

- Reaction score

- 38,415

- Location

- Extreme Southeast CA

Earth drillingSomeone will probably ask what this metal is for

- Local time

- 12:52 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,678

- Reaction score

- 38,415

- Location

- Extreme Southeast CA

- Local time

- 3:52 AM

- User ID

- 18248

- Joined

- Aug 14, 2021

- Messages

- 509

- Reaction score

- 2,106

- Location

- NorthCountry

Nice old lathe.

Too bad that 1. it's clear across the country, 2. I just spent all my playdough on four saws and 3. I dont know how to use one.

Other than that it would look cute tucked in a corner of my shop.

Too bad that 1. it's clear across the country, 2. I just spent all my playdough on four saws and 3. I dont know how to use one.

Other than that it would look cute tucked in a corner of my shop.

Similar threads

- Replies

- 78

- Views

- 9K