awol

Pinnacle OPE Member

- Local time

- 12:54 PM

- User ID

- 406

- Joined

- Jan 4, 2016

- Messages

- 628

- Reaction score

- 4,038

- Location

- Cabool, MO.

I have over a hundred chains through my TEMCo grinder.

On the plus side, it does a good job if maintenance and adjustments are applied, is kinda fun to watch, the chains cut every bit as good as ones off my Foley or filed, and let's me do something else while it works. Also it has no trouble doing chains with two left or right cutters in series. Setup and run-in was real easy, my 12 year old boy pulled it out of the box and had it grinding good within 15 minutes.

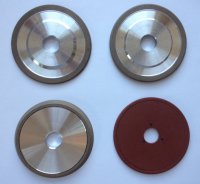

On the negative side, it struggles greatly to read the cutters on 3/8 LP that's not full chisel, and also some .404 that is full chisel. It also won't hog off a large amount of material in one pass, so I just use the Foley for rocked chains. The stone that came with the grinder is some kind of bonded emory compound. It works well if kept clean, but I modified a course white stone and it works better for dirty chains.

On the plus side, it does a good job if maintenance and adjustments are applied, is kinda fun to watch, the chains cut every bit as good as ones off my Foley or filed, and let's me do something else while it works. Also it has no trouble doing chains with two left or right cutters in series. Setup and run-in was real easy, my 12 year old boy pulled it out of the box and had it grinding good within 15 minutes.

On the negative side, it struggles greatly to read the cutters on 3/8 LP that's not full chisel, and also some .404 that is full chisel. It also won't hog off a large amount of material in one pass, so I just use the Foley for rocked chains. The stone that came with the grinder is some kind of bonded emory compound. It works well if kept clean, but I modified a course white stone and it works better for dirty chains.

Last edited: