You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tecomec Super Jolly for $270?

- Thread starter Ryan Browne

- Start date

- Local time

- 12:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,435

- Location

- East Jordan, MI

Yep agreed. I was trying to get our end of it as close as I could. There may be manufacturing differences built in that we can’t fix, but doing this at least gets us close.@huskihl

When this is set @ say 55-25-10, rights are done, when rotating to the lefts, 25* & 10* are both moving components/settings, the tooth length can still be different unless you are just absolute dead nuggets on both settings when resetting. Correct? It’s not like we are going to use test indicators & dial the prig in each time. This is where the tooth stop is the final/finesse adjustment, all the other chit is just ball park correct? What’s your acceptable deviation in tooth length?

I don’t know what I’d consider acceptable. Just figured if they were all sharp and the same length, and the rakers are all the same, if it cuts crooked I can blame something else. Mine are about .005” different from cutter to cutter and side to side. Like you said, depends on how you hold your tongue

- Local time

- 12:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,435

- Location

- East Jordan, MI

None taken at all.No sarcasm was intended with that statement @huskihl

They’re a pretty sweet grinder

- Local time

- 12:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,435

- Location

- East Jordan, MI

As is, but every 3 or 4 grindings I’ll back the chain off and lower the wheel to clean out the gullet. Haven’t round filed in a few yearsDo you guys run the chains as is off the grinder, or do you hand file the gullet a little more?

Lightning Performance

Here For The Long Haul!

- Local time

- 12:21 AM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Looks like I'm going zero degrees for most of my cutters here so round and square are one in the same

What is the top end grinder with the auto hydraulic vice built in?

What is the top end grinder with the auto hydraulic vice built in?

- Local time

- 12:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,435

- Location

- East Jordan, MI

It’s the name of the threadLooks like I'm going zero degrees for most of my cutters here so round and square are one in the same

What is the top end grinder with the auto hydraulic vice built in?

Lightning Performance

Here For The Long Haul!

- Local time

- 12:21 AM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Just checking.It’s the name of the thread

My machine is hardly used 2004 model from the other plant location in Italy.

Three grinders now so the Chicago crapper is going to do drags or maybe use the 399 B&F.

Can the switch be bought in a three way so I don't have to add the toggle on a box?

AM is fine.

Going to read this thread again.

- Local time

- 12:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,435

- Location

- East Jordan, MI

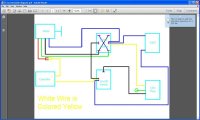

Not sure about the switch. @Moparmyway had a diagram showing how to wire for the “on off on” switchJust checking.

My machine is hardly used 2004 model from the other plant location in Italy.

Three grinders now so the Chicago crapper is going to do drags or maybe use the 399 B&F.

Can the switch be bought in a three way so I don't have to add the toggle on a box?

AM is fine.

Going to read this thread again.

- Local time

- 11:21 PM

- User ID

- 7126

- Joined

- Aug 23, 2018

- Messages

- 4,647

- Reaction score

- 27,600

- Location

- IA

I am all hand filed till now, the main reason I got them was to even a bunch of my chains up, ( tooth length & angles). I hit a lot of wire, nails, fence staples in fencerow trees. I will just run them off the grinder then clean the gullets by hand as needed.Do you guys run the chains as is off the grinder, or do you hand file the gullet a little more?

Philbert

Chainsaw Enthusiast

- Local time

- 11:21 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,054

- Reaction score

- 21,659

- Location

- East Dakota

Do you guys run the chains as is off the grinder, or do you hand file the gullet a little more?

+1. . . every 3 or 4 grindings I’ll back the chain off and lower the wheel to clean out the gullet.

If they need it, I will back off the chain stop a little, after sharpening both sides, and quickly 'run the gullets'. Does not have to be as precise as the edges.

Philbert

- Local time

- 11:21 PM

- User ID

- 7126

- Joined

- Aug 23, 2018

- Messages

- 4,647

- Reaction score

- 27,600

- Location

- IA

After scrounging thru the iron pile & cobbling something together. I found 2 Oregon grinder stands on Amazon for $18 each & free shipping. They look solid enough & stabile. Soooo, I guess I won’t have to manufacture another one tomorrow.

- Local time

- 12:21 AM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

Just checking.

My machine is hardly used 2004 model from the other plant location in Italy.

Three grinders now so the Chicago crapper is going to do drags or maybe use the 399 B&F.

Can the switch be bought in a three way so I don't have to add the toggle on a box?

AM is fine.

Going to read this thread again.

The motor is a split phase fractional horsepower capacitor start/run.Not sure about the switch. @Moparmyway had a diagram showing how to wire for the “on off on” switch

If you’re looking to use a reversing switch, you must reverse the leads to the cap or to the field wires. Not both, just one, either the cap or the field.

You could also use a drill to spin it backwards, then turn it on, and she will remain running with the wheel spinning backwards. Leaves you without having to add or wire into anything

Last edited:

Lightning Performance

Here For The Long Haul!

- Local time

- 12:21 AM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Mill chainI usually hand file my chains but when they are real bad, he just usually touches them up. This is damn near new chain and the rakers are at about .060

I like it.How are joo guys liking this Super Jolly? I'm *this* close to ordering one. Just wanted to see if it's still to your liking. Any pics of the finished chain? That might be the final straw on me biting.

I just checked the 404 for a guy. Use newer Orgon 404 presets or RS. They are the same.Yea I really do not like re using old presets, but some of the chain is old Oregon 52 and some Carlton. Have not been able to find presets anywhere. If anyone has a stash of Oregon 52 presets (404 chain .063) I will buy. I can see the manufacturers changing cutter design but why mess with the rivet diameter on presets?

I have a good supply of 27 presets for 404 and 72 presets for 3/8.

Just buy one. You order one yet?The cut is what I am mainly concerned with. If it cut close to hand filing then I would consider.

How the finished ground chain cuts in wood is key for me.

Hurst T handleI really liked your idea of, and logic behind, the big red handle to replace the chintzy little thread bobbin that comes with it. So I decided to engage in some classic Godd Ol' Boy Oneupsmanship and head to the stores to see what I could find. I was originally looking for an old style Hurst tee shifter handle but when I saw this my search stopped. Autozone.

View attachment 171160

Frigging BAD

Guess I am lucky, I live out at the end of the road on Washington's Olympic Peninsula.[/QUOTE]

Yup. My peninsula is all clogged up with people except for the middle and swampy bottom. Yours is betterer.

Where the hell was this last spring??? Took me two days of head scratching before I took it apart in the spring. 404 was off 0.030 in the vice. I was always adjusting the other side of the loop doing 3/8" chain.When you move your gauge selector, the .050, .058, .063…, the front side of the vise moves. When you pull the grinder head down, the back side of the vise moves. If the front half of your vise is set too far back, towards the inner vise, it will clamp your chain too far back, resulting in the left cutter being long. And when you change to do your right hand cutters, it will be clamping that side closer to the back which will result in a shorter cutter.

So here’s what I did…

Set your sliding axis at 0° in and out. Set your grinder to 25° and tilt the head to 55. Very lightly grind a left hand cutter and swing the vise the other way and grind a right hand cutter. Measure them. If your left cutter is longer, you need to turn your gauge dial to the right, which will allow the chain to be clamped closer to you, resulting in a shorter left hand cutter. If your left cutter is shorter, do the opposite.

Remove the snap ring on your gauge dial and reset it to whatever gauge chain you have. If the gauge dial doesn’t allow enough travel, like how mine was delivered, you’ll need to remove the snap ring before you get both cutters the same length and adjust it from there. And then once everything is all set with both cutters the same length and your gauge dial reading the same as your chain gauge, replace the snap ring.

Last edited:

Lightning Performance

Here For The Long Haul!

- Local time

- 12:21 AM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Knew about the wire swap. Need a drop in switch.The motor is a split phase fractional horsepower capacitor start/run.

If you’re looking to use a reversing switch, you must reverse the leads to the cap or to the field wires. Not both, just one, either the cap or the field.

You could also use a drill to spin it backwards, then turn it on, and she will remain running with the wheel spinning backwards. Leaves you without having to add or wire into anything

View attachment 231109 View attachment 231110

Running it on a back spin...

Won't that cause extra heat or affect the switch load?

Lightning Performance

Here For The Long Haul!

- Local time

- 12:21 AM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Thanks

@Moparmyway

@Moparmyway

- Local time

- 12:21 AM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

If you wire it hot to a 3 position DPDT switch, you might be able to use just one switch, but one winding of the field would be hot all times it’s plugged in. The second picture shows how i got two switches in the spot the factory has the one switch inKnew about the wire swap. Need a drop in switch.

Running it on a back spin...

Won't that cause extra heat or affect the switch load?

no, just spinning in the opposite direction, same load in either direction

Thanks

@Moparmyway