A dimple is one way of making a turbulator there are many different types.

Forget the golf ball thing that's just one application of thousands using turbulaters.

Why turbulaters? Here's the basics of how it works take a car with dust or rain drops on the hood now do 90mile an hr down the road notice the dust or drops of rain don't move.

That's because of the boundary layer it is a layer of air stuck to the hood that does not move it is sticky and creates drag for the air passing over it.

Turbulaters make the boundary layer of air disappear also making the surface slippery to air flowing over it.

Take a cylinder like an intake manifold apart from making the walls slippery you also pick up volume there is no boundary layer of none moving air taking up space as before.

There is lots of reserch going into Turbulaters now days they are finding there way into all kinds of things making them more efficient like Aviation/wind turbines/cycling/air conditioner systems in big buildings moving lots of air/engines you name it anything that has air passing over or through it, it's big business with new patents getting submitted all the time the race is on as to what type of turbulaters are best for an application still lots of reserch to do but a few men are going to be rich when they work this all out.

From what reserch I have read they work with fast or slow moving air and in high or low pressure zones.

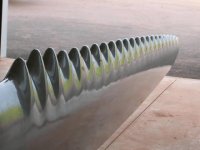

Turbulaters have been used in chainsaw rubber intakes for many years.

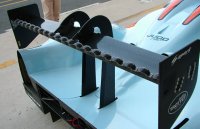

Some race shops offer cnc dimmpled heads now with dyno and flow sheets showing the gains.

But yes true you will always get the good old that will never work from guy's that never think out of the box or try anything new.

1st pic is of my 088 as you can see the turbulaters made into the rubber intake at the factory by Stihl the dimples are my doing with me good old Dremal lol

View attachment 205567 View attachment 205568 View attachment 205569