el33t

Super OPE Member

- Local time

- 9:09 AM

- User ID

- 29908

- Joined

- Aug 28, 2024

- Messages

- 251

- Reaction score

- 611

- Location

- Poland

So I've recently written several times in different places that in the chart for the Stihl USG grinder, the vise offset is probably in the opposite direction than needed for the LH and RH cutters.

Although it was pretty obvious I couldn't quite believe it, because such information was also in the oldest versions of the chart I could find. And this can probably be counted in decades by now.

Every now and then I would check for a newer version, where maybe something had changed, although I didn't really believe that someone would finally figure it out in 2024 instead of e.g. 2014 and make a correction.

But finally a version dated 2024 appeared, and to my surprise someone in it corrected that direction of the vise offset. What a coincidence!

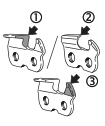

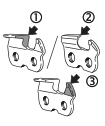

They did it, as I had previously hypothesized, by swapping the drawings of the LH and RH cutters.

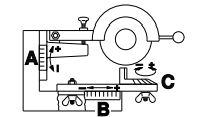

Previously, the LH cutter was numbered 1 and the RH cutter was numbered 2. After the change, the left one is number 2 and the right one is number 1. This made the fourth column (scale B) in the chart finally make sense.

Old version:

New version:

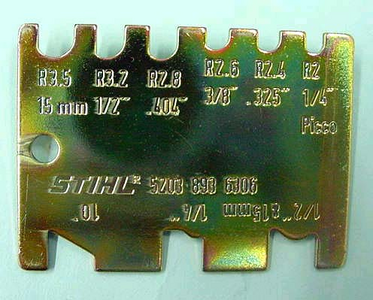

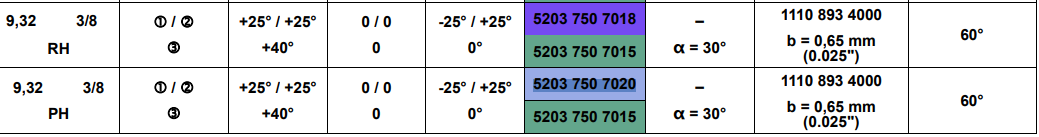

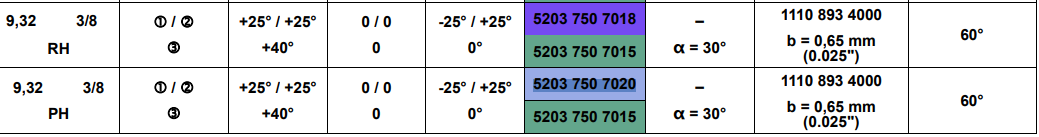

In this latest chart, there is an additional row where PH designation appears in the first column, which I believe heralds the arrival of Picco Hexa chain in Stihl's lineup alongside the already existing Rapid Hexa (RH). PH grinding wheel P/N is 5203 750 7020.

This makes sense given, in my opinion, the Hexa's biggest (and the only?) advantage, namely the ease of using the file without a guide by eliminating the most common sharpening mistake, namely holding the file too low. This allows the average user to get the right angles. And 3/8 LP/Picco/Mini/Hobby chains seem to be the most popular in chainsaws intended for the non-professional user, especially with the increasing prevalence of electric saws.

Of course, in my humble opinion, Stihl has not shied away from other mistakes in this version of the chart, which also existed before. The first one related to Hexa (or RH and PH now): the row for RH and duplicated from it the values for PH contains probably the wrong cutting angle given, i.e. scale A. They give it 25° (65° in Tecomec units), which makes no much sense given their expected value for the side plate angle of 60° (not 65°). Besides, the witness mark on the side plate is at 60°, well, and the file is hexagonal (6 × 60° = 360°).

In this case, it is likely that the settings for the C scale (25°) somehow ended up in the A scale by mistake.

In summary, the A scale setting for Hexa (RH & PH) should be 30° instead of 25°.

Another suspicious case is the settings for Rapid Duro (RD) chain. The specified angle for the A scale is 20°, which corresponds to a cutting angle of 90° - 20° = 70°. In contrast, the expected side plate angle is 65°. It seems that the value for the A scale should be 30°, not 20°.

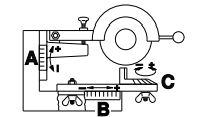

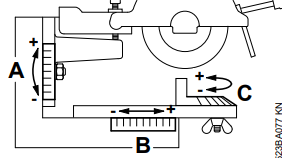

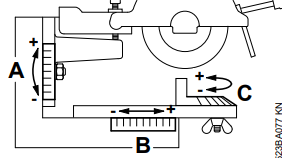

Finally, a trivial error, if it is an error, because it is a matter of interpreting the drawing. The direction of rotation of the vise for negative values of the C scale is clockwise, while it should be counterclockwise.

Chart:

Manual:

PS

A YT user noted that they did not change the +,- signs for the 5th column of the chart, which is the C scale (top plate angle). As a result, after correcting one error, another error appeared. Of course, in this case, everyone should quickly realize that such a sharpened chain is unlikely to be suitable for cutting anything.

Although it was pretty obvious I couldn't quite believe it, because such information was also in the oldest versions of the chart I could find. And this can probably be counted in decades by now.

Every now and then I would check for a newer version, where maybe something had changed, although I didn't really believe that someone would finally figure it out in 2024 instead of e.g. 2014 and make a correction.

But finally a version dated 2024 appeared, and to my surprise someone in it corrected that direction of the vise offset. What a coincidence!

They did it, as I had previously hypothesized, by swapping the drawings of the LH and RH cutters.

Previously, the LH cutter was numbered 1 and the RH cutter was numbered 2. After the change, the left one is number 2 and the right one is number 1. This made the fourth column (scale B) in the chart finally make sense.

Old version:

New version:

In this latest chart, there is an additional row where PH designation appears in the first column, which I believe heralds the arrival of Picco Hexa chain in Stihl's lineup alongside the already existing Rapid Hexa (RH). PH grinding wheel P/N is 5203 750 7020.

This makes sense given, in my opinion, the Hexa's biggest (and the only?) advantage, namely the ease of using the file without a guide by eliminating the most common sharpening mistake, namely holding the file too low. This allows the average user to get the right angles. And 3/8 LP/Picco/Mini/Hobby chains seem to be the most popular in chainsaws intended for the non-professional user, especially with the increasing prevalence of electric saws.

Of course, in my humble opinion, Stihl has not shied away from other mistakes in this version of the chart, which also existed before. The first one related to Hexa (or RH and PH now): the row for RH and duplicated from it the values for PH contains probably the wrong cutting angle given, i.e. scale A. They give it 25° (65° in Tecomec units), which makes no much sense given their expected value for the side plate angle of 60° (not 65°). Besides, the witness mark on the side plate is at 60°, well, and the file is hexagonal (6 × 60° = 360°).

In this case, it is likely that the settings for the C scale (25°) somehow ended up in the A scale by mistake.

In summary, the A scale setting for Hexa (RH & PH) should be 30° instead of 25°.

Another suspicious case is the settings for Rapid Duro (RD) chain. The specified angle for the A scale is 20°, which corresponds to a cutting angle of 90° - 20° = 70°. In contrast, the expected side plate angle is 65°. It seems that the value for the A scale should be 30°, not 20°.

Finally, a trivial error, if it is an error, because it is a matter of interpreting the drawing. The direction of rotation of the vise for negative values of the C scale is clockwise, while it should be counterclockwise.

Chart:

Manual:

PS

A YT user noted that they did not change the +,- signs for the 5th column of the chart, which is the C scale (top plate angle). As a result, after correcting one error, another error appeared. Of course, in this case, everyone should quickly realize that such a sharpened chain is unlikely to be suitable for cutting anything.

Last edited: