First … I'm no expert, I'm a newbe, but I'll add my 2 cents cause what I have been doing seems to work for me.

I generally view the intake and exhaust differently because exhaust gasses are under much great pressure, with combustion expanding them by approximately ten fold. I also think that makes it important to maintain some reverse funnel shape for the exhaust port.

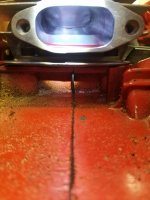

As a result, I try to make the exhaust as wide as the skirt will safely allow, try to flatten to top (not completely, don't want to hang a ring), but eliminate any excessive arch. This often makes it a little wider on the inside than on the outside, but I don't widen it the full depth, the start is most important on the exhaust and that reverse funnel function. So, I often shape it a bit like a trapezoid, being a little wider on the top.

I first make sure the outside it at least as wide as the gasket, then generally open it a bit more, and the gasket and muffler. I also don't spend time mirror polishing the exhaust port (but I do try to get it as smooth as possible). I think that is more for race saws than working saws.

Right or wrong, that is how I do it, and it seems to work in the saws I've been porting.