Taking off little bits at a time is a function of your grinding wheel. If you get a COARSE grinding wheel you don't have to worry as much. People get all to concerned with how the finish of the cutter looks and lots of people love the Molemab grinding wheels for this reason. I think they are horrible myself... They are about 80grit and leave a nice finish but are slow to cut, easy to get build up (black ring of death), and thus heat your cutter quicker. Oregon's are usually around a 60grit and cut quicker and stay cooler. I'm not sure if there is a coarser grit that that for Oregon grinders but if there is... Buy the coarse one! Stihl USG grinding wheels have to be at least a 45-55 grit from comparing them side to side with oregon 60grit wheels and I eat a big chunk off 404 chain in a single swipe and then double tap it to clean it up. I wouldnt go any more than 45-55 grit but 80 grit is just too fine and builds up with all the oil from used chain.

keep your wheel well dressed.

As for the 520 Oregon Grinder... its basically an updated version of the old 511a. A few more features and a triangular hold on the chain vise now instead of a 2 point pinch system. Dave sent me one a while back and I set it up and it works well. Better than the old 511a and better than the Oregon knock offs but still not my favorite.

1.) Check your angles to make sure you are getting the same top plate angle from side to side. Seems like Dave's was off by 4-6*. Not a big problem but if you are being picky you can mark your vice to be more accurate.

2.) Also check the top plate length when you are grinding from side to side because I'm pretty sure Dave's 520 was off by 0.010-0.015. Again not a huge deal but keeping the chain symetrical from side to side will help keep cuts strait.

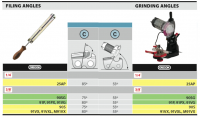

3.) Use OEM chain charts to set your angles. Chain manufactures know more than us on why the OEM angles are what they are. Chain is designed and manufactured to use certain angles so setting up your machine to grind the same way it came from factory is a good idea. Oregon chain angles can be found in their 2017 Catalog start at about page 110-111 for chain info and specs.

http://content.yudu.com/web/y5b2/0A...h/resources/index.htm?referrerUrl=#noRedirect

Stihl chain charts will not give you the right angles for your Oregon grinder. If you are grinding Stihl chain their angles are set in reverse of the Oregon grinders so keep that in mind.