- Local time

- 10:15 AM

- User ID

- 28875

- Joined

- Apr 5, 2024

- Messages

- 1,223

- Reaction score

- 5,791

- Location

- Wyoming

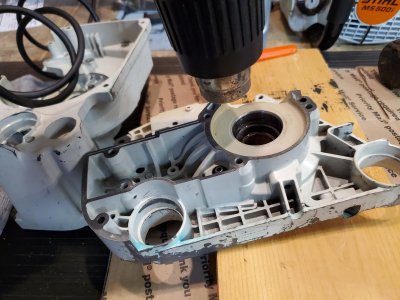

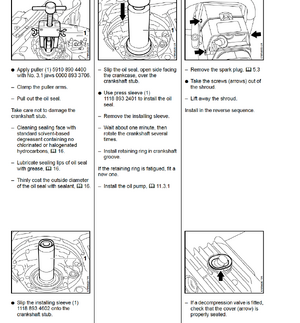

I recently got my project ms460 together. Started and ran good, but then started acting like it had an air leak after a little bit. I pressure tested it, and found the PTO side seal wasn't sealing right - the outer lip was slightly over the groove where the oiler snap ring rides, and was leaking. I tapped it in some more to get the lip to seal. It pressure tested fine.

Ran it again, and after a little while, started acting funny again. Pressure tested again, and the seal wasn't sealing. Popped the seal out, and found that the inside lip had been rubbing against the inner bearing race from being tapped in too much, and had started to fall apart. Good thing I caught it before the spring had time to come apart in the crankcase.

Tapped in a new seal, and I went too far in again. I could see the rubber bulging out because it had again bottomed out on the PTO bearing inner race.

I'm beginning to think that I messed up on this one. I used the Wolf Creek Saw Shop kit with SKF/New West bearings. I'm wondering if the PTO bearing dimensions are different, causing there to be not enough room for the seal to seat perfectly between the oiler snap ring channel and the inner bearing race.

Does anyone else have this experience? Can anyone share pictures up close of their PTO side seal riding on the crankshaft? I'm curious about how close the factory outer seal lip is to the snap ring groove.

I have a feeling that I'm going to have to split cases again...

Ran it again, and after a little while, started acting funny again. Pressure tested again, and the seal wasn't sealing. Popped the seal out, and found that the inside lip had been rubbing against the inner bearing race from being tapped in too much, and had started to fall apart. Good thing I caught it before the spring had time to come apart in the crankcase.

Tapped in a new seal, and I went too far in again. I could see the rubber bulging out because it had again bottomed out on the PTO bearing inner race.

I'm beginning to think that I messed up on this one. I used the Wolf Creek Saw Shop kit with SKF/New West bearings. I'm wondering if the PTO bearing dimensions are different, causing there to be not enough room for the seal to seat perfectly between the oiler snap ring channel and the inner bearing race.

Does anyone else have this experience? Can anyone share pictures up close of their PTO side seal riding on the crankshaft? I'm curious about how close the factory outer seal lip is to the snap ring groove.

I have a feeling that I'm going to have to split cases again...