redline4

I'm huge in Japan

- Local time

- 7:48 PM

- User ID

- 5593

- Joined

- Mar 12, 2018

- Messages

- 11,554

- Reaction score

- 94,736

- Location

- Rosholt Wisconsin

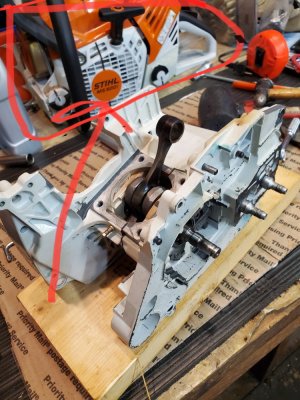

There may already be a thread, but I didn't see one on a quick search.

Either way, I'm putting one together so thought I would do a build thread.

Expect delays while I wait for parts, time or backtrack because I got ahead of myself.

Also, there's multiple ways of doing it and some better than my way, but this works for me.

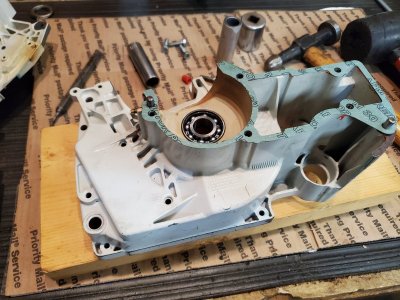

I started with the pto side case and bolted up the oil pump

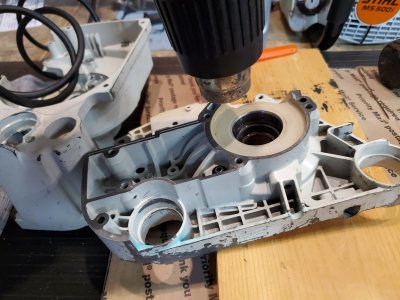

Oem proprietary bearing.

And with my heat gun, warm up the case..

Once it's ready, the bearing pretty much drops in and bottoms out on the previously bolted up oil pump. I keep a 1" socket close by in case a few light taps are required.

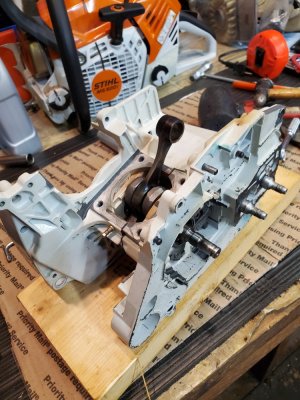

After that, I install the flywheel nut on the crank to keep the threads from getting boogered.

By the time I'm done with that, the heat from the case has soaked into the bearing. I will usually apply a little more heat if it's too cool.

And the crank drops in.

If necessary I will give it a few taps with a rubber mallet. I also support the inner bearing race with a piece of pipe. That will be in upcoming pics as only 5 pics per post are allowed.

Either way, I'm putting one together so thought I would do a build thread.

Expect delays while I wait for parts, time or backtrack because I got ahead of myself.

Also, there's multiple ways of doing it and some better than my way, but this works for me.

I started with the pto side case and bolted up the oil pump

Oem proprietary bearing.

And with my heat gun, warm up the case..

Once it's ready, the bearing pretty much drops in and bottoms out on the previously bolted up oil pump. I keep a 1" socket close by in case a few light taps are required.

After that, I install the flywheel nut on the crank to keep the threads from getting boogered.

By the time I'm done with that, the heat from the case has soaked into the bearing. I will usually apply a little more heat if it's too cool.

And the crank drops in.

If necessary I will give it a few taps with a rubber mallet. I also support the inner bearing race with a piece of pipe. That will be in upcoming pics as only 5 pics per post are allowed.