slackinoff

Pinnacle OPE Member

*Moderators - this might be more appropriate in the clone section, feel free to move pls*

Does anyone know if the Walbro HD-12B "EPA" has any differences from the non EPA version besides the limiting screws? This carb will not fully lean out, even with the high jet fully closed up (limiting caps are removed). The low jet is set to about one turn. I bought this carb brand new in box.

This is on a clone 372 OE - I built it last year and have been playing with. It doesn't have much run time. I swapped the Chinese copy on it last night and am going to run it after work today.....I never ran the saw with the included Chinese clone HD-12.

I will be kind of shocked if I can get the clone carb to lean out properly....it will make me think these EPA versions have another difference to them than just the limiting caps.

Does anyone know if the Walbro HD-12B "EPA" has any differences from the non EPA version besides the limiting screws? This carb will not fully lean out, even with the high jet fully closed up (limiting caps are removed). The low jet is set to about one turn. I bought this carb brand new in box.

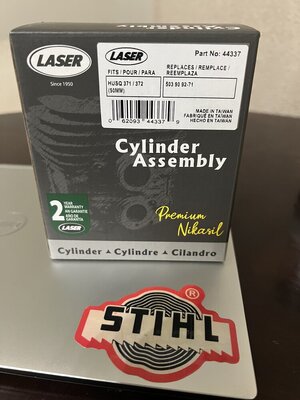

This is on a clone 372 OE - I built it last year and have been playing with. It doesn't have much run time. I swapped the Chinese copy on it last night and am going to run it after work today.....I never ran the saw with the included Chinese clone HD-12.

I will be kind of shocked if I can get the clone carb to lean out properly....it will make me think these EPA versions have another difference to them than just the limiting caps.

Last edited: