- Local time

- 7:09 PM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

yes, I know you enjoy ribbin me

The 372 I just did got stuck when it was part way together. I pulled it the rest of the way with a similar tool to Matt's. It spun absolutely free when I was done. Kinda surprised me.I've put the pto bearing in and had it fall all the way through when they were plenty warm. If I have to pull the cases together any with bolts the crank doesn't turn very free. If they drop together by hand it's usually free spinning.

Yep. I may make a set for the clutch side of a 372 and the 44/46/66The 372 I just did got stuck when it was part way together. I pulled it the rest of the way with a similar tool to Matt's. It spun absolutely free when I was done. Kinda surprised me.

I'll always use heat but these tools have their place. I made mine to push the seals in. I think that's where they'll really shine.

All the dimensions are in Tor's thread in the technical section. 1 1/2" round stock works perfect.Yep. I may make a set for the clutch side of a 372 and the 44/46/66

Mike, you only need to make 6 bolts and you have covered pretty much the whole line up to Husky from around 1985 and until today.Yep. I may make a set for the clutch side of a 372 and the 44/46/66

Really good video Matt have used heat and freezer for years will have to try your method on my next project thanks for sharing very informative my friend thanks for sharing

372 crankcase assembly.... GOT IT

never thought we needed tools for 340/345/350 since they are clamshell design.Essential info there Tor... thanks.

I know husky 340, 345, 350 and 455 rancher all use the same pto and flywheel side threads as 346xp ... so you can add those to that list

Those shop tools are very nicely made, but I like my version 2.0... I can use my impact on it if I want

the only one I didnt add in the system is threads for 133/234/238/42/242/246 since those saws are super rare.oh, since those pto sides are all left hand thread, likely I need to expand my collection of taps a bit...

Really good video Matt have used heat and freezer for years will have to try your method on my next project thanks for sharing very informative my friend thanks for sharing

With some bad clutches with busted spiders and a little welding I can probably make all of mine and not need the left hand taps.Mike, you only need to make 6 bolts and you have covered pretty much the whole line up to Husky from around 1985 and until today.

Here is an overview of thread system Husky has used:

View attachment 58936

Your bolts should be threaded 60mm, its always best to have a bit longer bolts then needed.

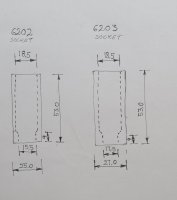

You need to lathe out two sockets, one for 15mm crank axel and one for 17mm.

View attachment 58938

Here is an OEM kit who fit 346:

View attachment 58939

There is a bit more reading here:

http://opeforum.com/threads/crank-mounting-tool-crank-threads.4804/