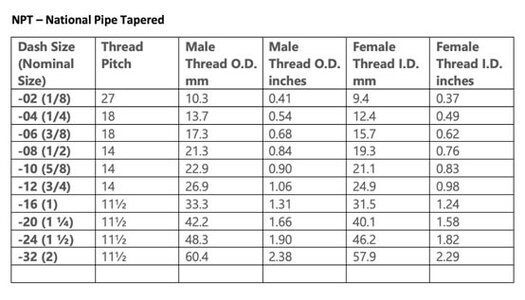

As far as drilling and tapping it- I am not saying it wouldnt work, but you have to take into consideration how thick that metal is- ist it even thick enough to get even two full threads in it, and pipe threads are spaced apart bigger and although there are straight pipe threads most are on a taper. If I was dead set on going the drill & tap route ( which I would not do personally ) I wild use the smallest diameter with a fine thread pitch to get the most threads in there. Just my 2 cents / opinion.