Two things:

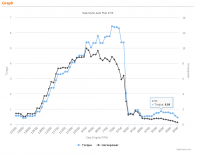

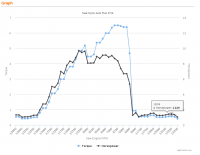

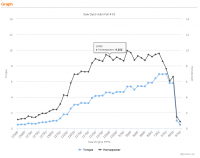

Hp it the most important # because it combines RPMs with torque at that RPM to produce "work", and my gut was right, I thought the 661 was a bit stronger than the 066, but looks like the 066 has a wider power band (which some may prefer). If the saw operator can keep the RPMs near max Hp, that saw will win the race (all other things being equal). The broader power band will be more forgiving for things like knots in the wood, pinched bars, etc.

Your optimum compression will vary based on the amount of air/fuel in the cylinder. As pointed out, SC & turbo motors have less compression because the charge volume is greater. To a lesser extent, the more you improve the ports (etc) to flow maximum charge volume into the cylinder, the less compression pressure you need to burn it optimally, and there can be a point of negative returns. It depends on many factors, so we just make an educated guess, but fuel octane, chamber design, hot spots, etc all play a role.

Fortunately, the dyno can let you know what does and does not work in your engine with your fuel!