You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chainsaw Porting Theory

- Thread starter Mastermind

- Start date

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

Let's talk a bit about EXHAUST now. Port placement, shape, pipes, etc....

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

Wider = more power, more square at the top flows more at the 1st crack of the port?Let's talk a bit about EXHAUST now. Port placement, shape, pipes, etc....

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

It's known that the exhaust is one of the more difficult areas for piston and ring stresses and wear.

A squarer roof will vent exhaust pressure faster, but be harder on the rings. Where's the balance on that one?

Roof placement in degrees is a critical measurement of engine behavior and performance. While there are exceptions to the rules very often, it's generally agreed that a physically lower roof will allow for a longer power stroke and produce more torque at a lower rpm. A higher roof will lend to a higher revving engine will some loss in low end grunt.

The roof also affects trapped volume, so ultimately how much charge one has for combustion and how much compression pressure an engine will develop.

A squarer roof will vent exhaust pressure faster, but be harder on the rings. Where's the balance on that one?

Roof placement in degrees is a critical measurement of engine behavior and performance. While there are exceptions to the rules very often, it's generally agreed that a physically lower roof will allow for a longer power stroke and produce more torque at a lower rpm. A higher roof will lend to a higher revving engine will some loss in low end grunt.

The roof also affects trapped volume, so ultimately how much charge one has for combustion and how much compression pressure an engine will develop.

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

I think more area=more power.Wider = more power, more square at the top flows more at the 1st crack of the port?

So Keith, let's say we take .040 from a squish band. We need to raise the exhaust (generally) to get back to our intended degree mark. So now we have made a larger port area with no widening, but it won't affect pressure in the BD period as much as a wide flat area would.

Then we have top builders here and elsewhere leaving the port at stock width when they build their fastest engines with finger ports because it necessitates the piston to be rotated 180* for the ring pins to not nibble the fingers.

Why is a stock width port OK in a super high performance mod, but not in a woods port?

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

My guess would be a degree or so peak in the center and tapered to the sides?

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

Then there's the issue of compression. Let's say I cut too much from my band. I check and I'm at 250psi of compression. I can raise the ex port to bleed that off at starting RPM. If I make a pointier roof or a wider bevel, I'm varying the duration a bit because at higher rpm, it will start trapping before the defect in the plating or the very small arc on the roof is fully closed.

An exaggeration of this would be the old McCullough T port. I'm pretty sure Stihl still uses this design on its cutoff saws.

An exaggeration of this would be the old McCullough T port. I'm pretty sure Stihl still uses this design on its cutoff saws.

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

I'm faced with a complicated jug issue now.

I'm doing a 262 jug. Because of a dull cutter on my mandrel and the effects of ethanol on the human brain, I'm stuck with .050 from the band and a squarish exhaust roof at 103*. Squish at .022.

My intake wound up at 79*, transfers are at 116.

So I wanted 103/116/75. So now I'm gonna have to be 101/116/79.

The raised intake should bleed comp down, I'm hoping to 210.

I'm doing a 262 jug. Because of a dull cutter on my mandrel and the effects of ethanol on the human brain, I'm stuck with .050 from the band and a squarish exhaust roof at 103*. Squish at .022.

My intake wound up at 79*, transfers are at 116.

So I wanted 103/116/75. So now I'm gonna have to be 101/116/79.

The raised intake should bleed comp down, I'm hoping to 210.

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

Deets066

AKA Deetsey

- Local time

- 9:55 PM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,593

- Location

- Illinois

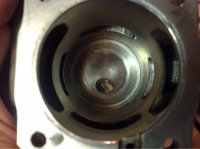

Corners of your exhaust are rounded nicely, should be fine. I wouldn't raise it anymore DocSo do I deal with this roof or raise it to a nicer arc?

Because of the smallish chamber, I believe I'm gonna raise it. This will also allow me to balance intake and exhaust durations.

I blended the squish to chamber interface quite a bit.

View attachment 12438View attachment 12439View attachment 12440View attachment 12441View attachment 12442

Sent from my iPad using Tapatalk

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

I cheated a bit Deets. Can you see it?Corners of your exhaust are rounded nicely, should be fine. I wouldn't raise it anymore Doc

- Local time

- 9:55 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

I raised the chamfer. So it's wider at the top and narrower at the edges.

The top of the chamfer is under the ring lip.

So the opening in the plating is slightly more arched in the center than the pics woul suggest.

I think I'm gonna raise it to 101.

The top of the chamfer is under the ring lip.

So the opening in the plating is slightly more arched in the center than the pics woul suggest.

I think I'm gonna raise it to 101.

- Local time

- 9:55 PM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

From past experience of hanging a ring in the exhaust .............. I'd round out that roof just a little more.

If you hang a ring ........... you wont need to worry about how it performs

If you hang a ring ........... you wont need to worry about how it performs

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

A good plan before hand is wise. Jumping in and opening things up too much can go south quickly. Thats why I usually throw ideas around with Mdavlee, Randy, Shaun, etc. Thoso guys have explored options and can and do save a man time and money if a man will ask for help. I sure can appreciate your interest, studying, and knowledge also as u have gotten a good grip on all this stuff!! Thanks for sharing and Im listening!!Then there's the issue of compression. Let's say I cut too much from my band. I check and I'm at 250psi of compression. I can raise the ex port to bleed that off at starting RPM. If I make a pointier roof or a wider bevel, I'm varying the duration a bit because at higher rpm, it will start trapping before the defect in the plating or the very small arc on the roof is fully closed.

An exaggeration of this would be the old McCullough T port. I'm pretty sure Stihl still uses this design on its cutoff saws.

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

Looks fine to me as that peak will blowdown alil quicker and taper down without taking as much roof out down to the edges? Saves some compression? Also if u wanna peak quicker and want more compression, take alil less out of the passage to the exhaust Window?I raised the chamfer. So it's wider at the top and narrower at the edges.

The top of the chamfer is under the ring lip.

So the opening in the plating is slightly more arched in the center than the pics woul suggest.

I think I'm gonna raise it to 101.

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

U have a slight stepdown on the floor if my eyes are workin right?So do I deal with this roof or raise it to a nicer arc?

Because of the smallish chamber, I believe I'm gonna raise it. This will also allow me to balance intake and exhaust durations.

I blended the squish to chamber interface quite a bit.

View attachment 12438View attachment 12439View attachment 12440View attachment 12441View attachment 12442

Sent from my iPad using Tapatalk

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

Plenty of arc in that roof ? Looks greatCorners of your exhaust are rounded nicely, should be fine. I wouldn't raise it anymore Doc

Brewz

Free Range Human in a Tax Farm

- Local time

- 1:55 PM

- User ID

- 550

- Joined

- Jan 16, 2016

- Messages

- 4,217

- Reaction score

- 14,326

- Location

- Hunter Valley - Australia

044 in front of me......

Do share...... I have one coming I am going to build up for my brother

Keith Gandy

Maxima K2 40:1 87 Pump Gas

- Local time

- 8:55 PM

- User ID

- 341

- Joined

- Dec 30, 2015

- Messages

- 6,219

- Reaction score

- 16,241

- Location

- Provencal, Louisiana

Man hangin a ring in a inake widened too much on a 460 is no fun either! Lol!! I found out the hard way!! U dont forget thoso kinda mistakes and learn quickly to measure/ calculate before widening!!From past experience of hanging a ring in the exhaust .............. I'd round out that roof just a little more.

If you hang a ring ........... you wont need to worry about how it performs