singinwoodwackr

Pinnacle OPE Member

- Local time

- 4:24 AM

- User ID

- 34279

- Joined

- Sep 14, 2025

- Messages

- 759

- Reaction score

- 2,196

- Location

- moon

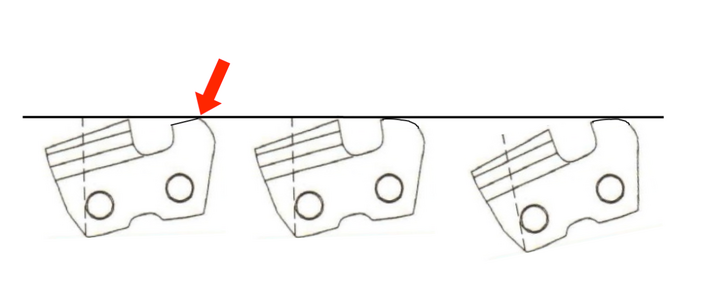

Thats fine for an occasional chain that just needs touching up. Try doing 20 rocked chains at a time…Have you cut with one of those chains yet? I find rakers on the grinder to be a tricky business and not that bad to just hit them each a stroke with the file.

I finally broke down and ordered a course flat cbn raker wheel to replace the regular cbn wheel I’ve had for a couple years.