- Local time

- 2:37 PM

- User ID

- 522

- Joined

- Jan 12, 2016

- Messages

- 4,196

- Reaction score

- 27,499

- Location

- Iowa City

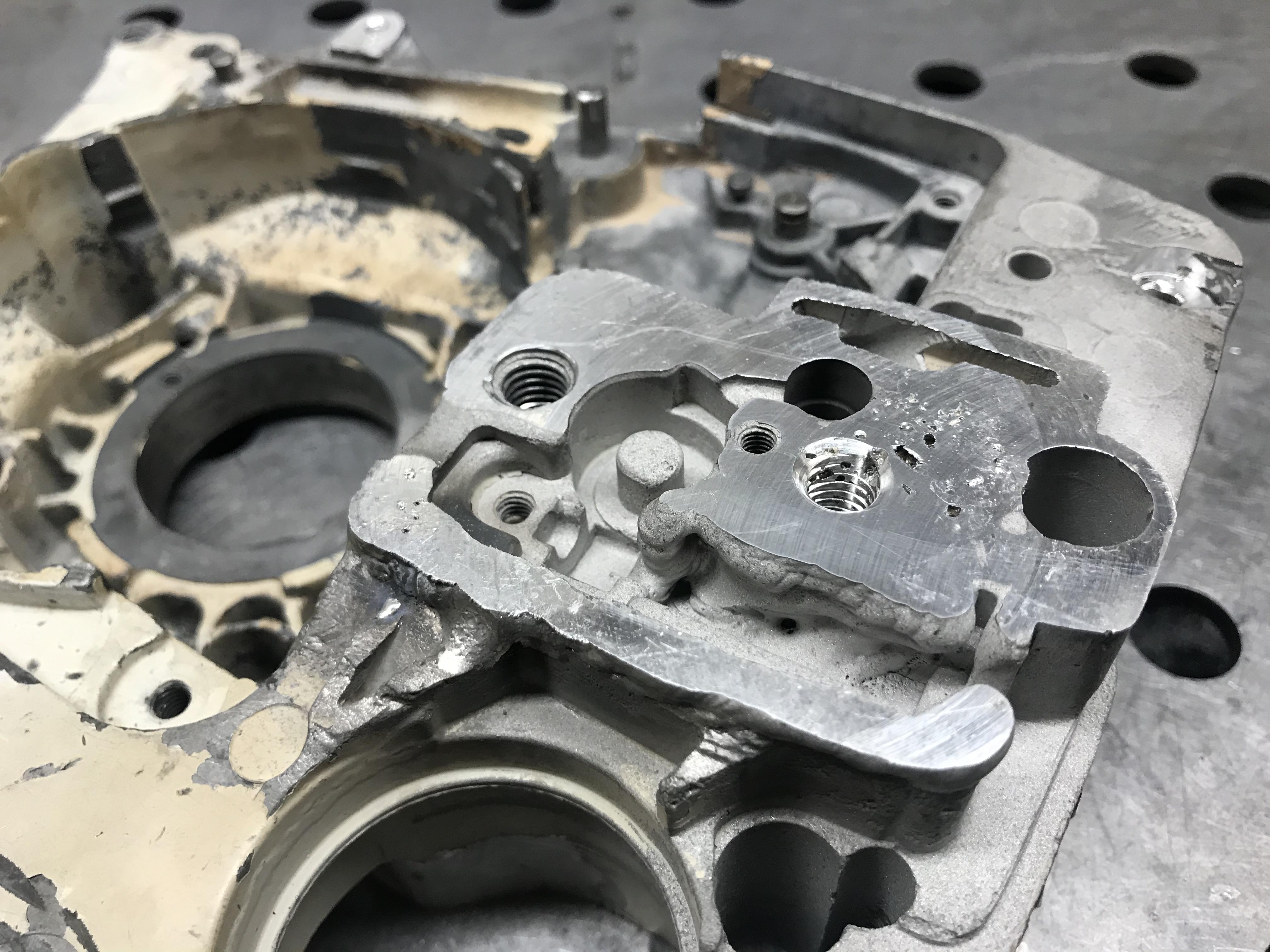

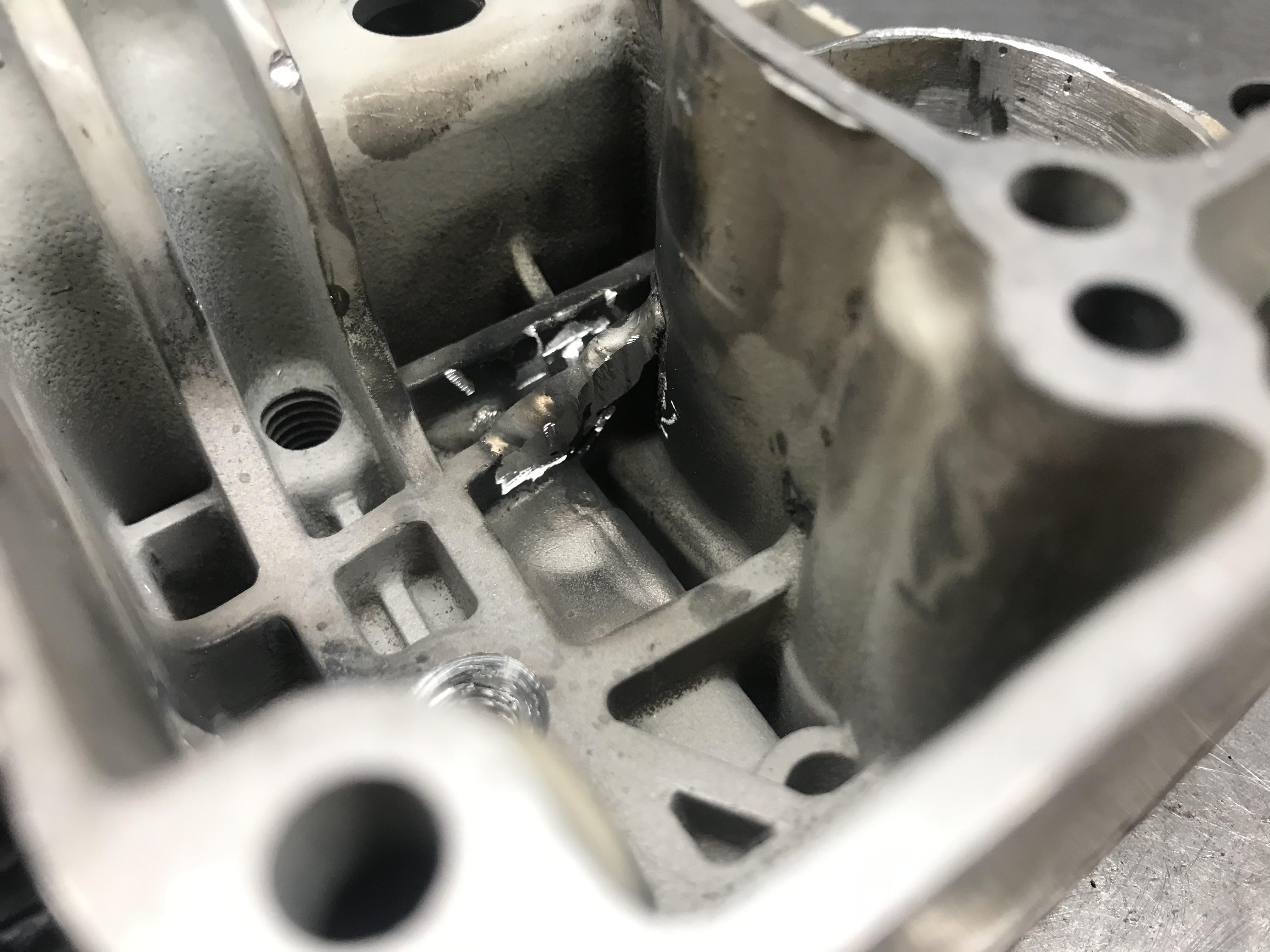

Got the new crack finished off. I added a bit of a wing inside the tank for more strength.

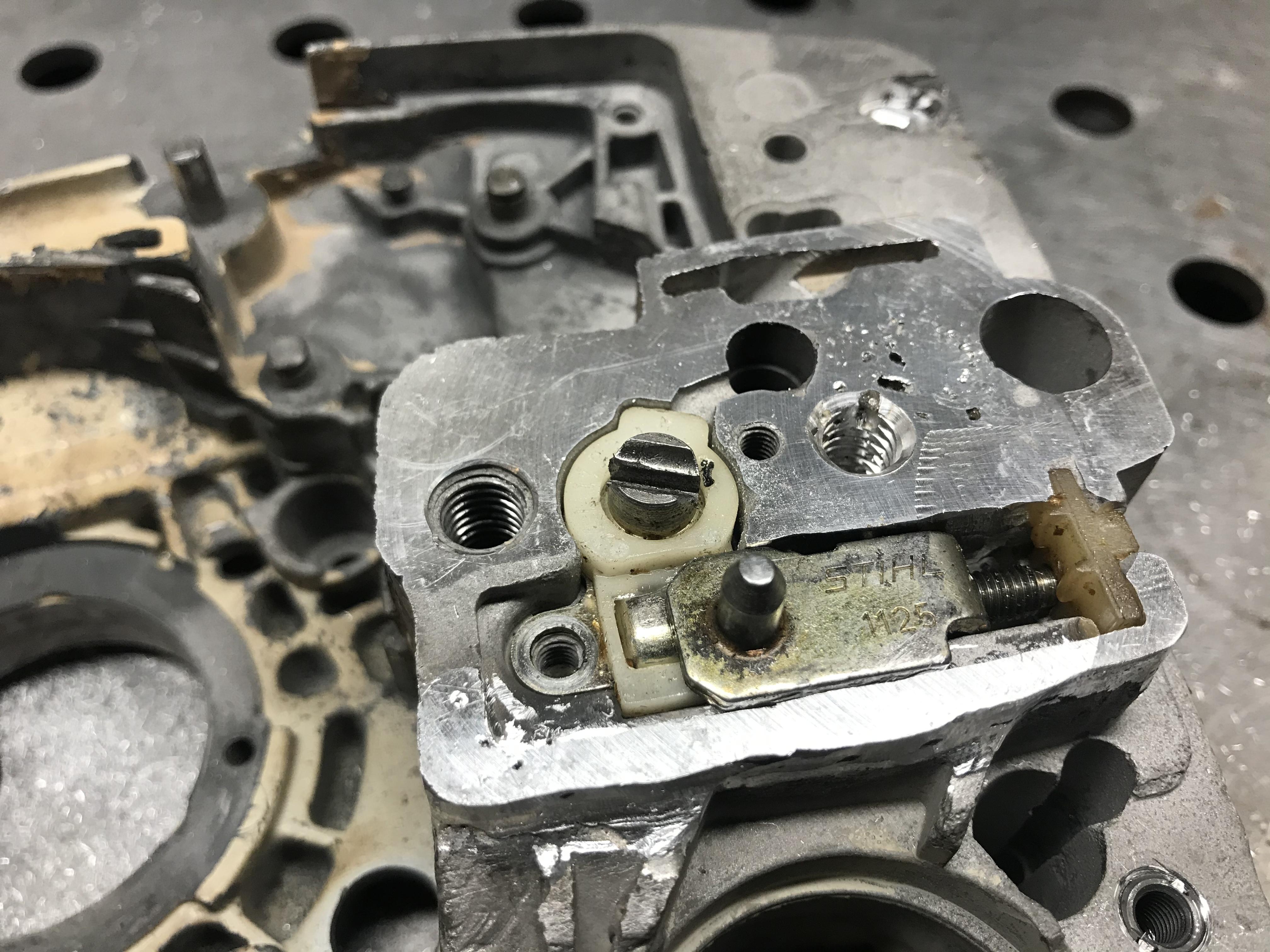

I also put a locking insert into the bottom bucking spike hole. It had a helicoil which is an acceptable fix but I wanted it right. I’ve welded these in the past but they are a pain. Really the best fix is these stake locking inserts.

I’ll have to knock the bar pad flat on the mill before I finish off the rest of the bar adjuster area. Then off to powder coat.

I also put a locking insert into the bottom bucking spike hole. It had a helicoil which is an acceptable fix but I wanted it right. I’ve welded these in the past but they are a pain. Really the best fix is these stake locking inserts.

I’ll have to knock the bar pad flat on the mill before I finish off the rest of the bar adjuster area. Then off to powder coat.