I'm pretty slack at recording things, but I’ve been into it twice now. So I do have some pic,s

The first time I took some timing numbers, and looked at the trans, what was going on here, when they made it. At first it thought a blind drunk person made it, cos of the slanty trans. Then I remembered that mastermind said it was to do with some backsuffin or something.

So as to masterminds methods, I got a ring and popped it into the cylinder and got it to the number I wanted. I cut me some card and started grinding. I don’t have the best tools so made do with the battery drill and a diamond wheel. I was sweating. Anyways job got done (a bit rough), I widened the intake as well as cleaning up the lower trans

The exhaust got a very slight raise, and I did lower the intake a little. They then got a 80/100 grit polish.

I did try a sans gasket. Well that didn’t work, due to the squish being a tad tight. Iirc, it was 16thou.

I pulled the carb to drill the main jet, I just could not justify the #70 micro drill (0.0295) as I had not really ported it to the max. So I opted for #73 (0.0250) originally it was 0.0200, well that’s what drill size fitted in.

The saw got put back together, with the oem gasket, and a little test , about a tank full. It seemed to rip,

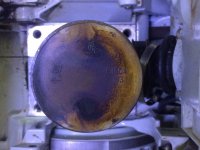

But I was not happy that the squish had not been set, so I tore it apart one more time. I took a. Pic of the wash on the piston. (Which I had cleaned previously)

This time I cut a coke can up and that with some dirco the squish was set 0.0200

Ive given it a tune,a tacho and some cutting

The tach says 13.5k then blipped to 13.8k. (Not sure why it blipped)

So that’s the testing vids above.

Cheers