- Local time

- 5:03 PM

- User ID

- 2014

- Joined

- Oct 21, 2016

- Messages

- 34,640

- Reaction score

- 147,461

- Location

- Kansas

McMaster Carr jas some different sleeve material.Well it looks like if I'm going to do this with the 660 piston it's going to be with a two piece cylinder. I've never done a two piece so it would be a great first time project.

I can use the 385 piston if I have sleeves made from milling a 13mm pin to the inside diameter of 12mm and cutting a couple pieces to length. Clips with big ears should keep the sleeves in place if I go that route. It's a scary thought to go using those sleeves like that but the pin itself is what gets the tension from the bearings so the sleeves might not create any extra force or wear on the clips.

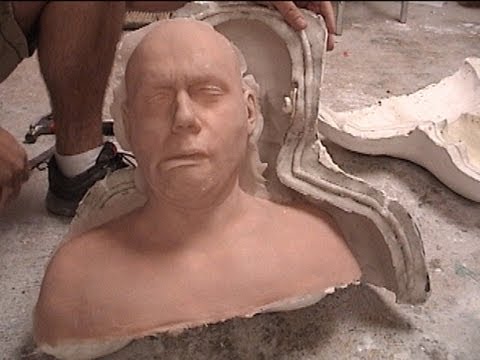

Tim aka Dieselfitter has some pics.Does anyone have a vid of pulling a crank apart?