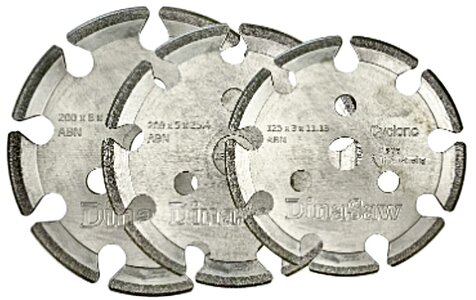

When guys first started talking about CBN / ABN wheels in these forums (when I still had dark hair), they were mostly referring to ones like the DynaSaw, ‘cyclone’, segmented, ABN wheels - about $300 each.

View attachment 409103

They were described as almost magical.

When the $100 wheels became available, with positive reviews, I splurged, and used some ‘birthday money’ to buy a pair of the Diamond brand wheels.

I was underwhelmed.

The finish I got was somewhat rough. I could still ‘burn’ a cutter if I held the wheel in place too long.

View attachment 409112

*They did produce less dust*.

But, results were nothing special over what I got with $15 -$20 Molemab, Tecomec, Total, etc., vitrified wheels , which lasted me a long time, could be profiled, etc.

If folks are happy with the performance they get, that is great. I like the results and value I get from the vitrified wheels.

If someone is new to grinding, I’d recommend putting that extra $200 into a better quality grinder, over a clone model, and trying the ‘standard’ wheels.

(But I still haven’t tried those ‘cyclone’ wheels!).

Philbert

especially if someone brings a chain that is several years old

especially if someone brings a chain that is several years old