Part 1

Part 1

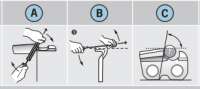

So, there are really 3 key angles when sharpening:

'A' is the 'Top Plate Filing Angle' (typically 25 to 35 degrees). This shapes the 'angle of attack' of the top plate, ***but also the cutting bevel angle of the side plate *** This is part of Joe Cox's design, to shape

both with one file pass!

'B' is the 'Down Angle' (typically 0 or 10 degrees). This makes a compound bevel in the top plate cutting edge. Called 'down angle' as you lower the file handle down to do this when filing from the inside-out.

'C' is the 'Top Plate Cutting Edge Angle' (typically 55 to 60 degrees), which is achieved by the height of the correct diameter file (or angle of the grinding wheel). We can get into all types of weird geometry here (cord angle of the file diameter), and confusing measurements, since there are few 90 degree angles on a cutter; the guide bars are crowned, not flat; it is a different angle if measured at the inside or outside edge (60 degree inside angle may measure 80 degrees at outside edge); etc.

This illustration is from the Oregon reference, mentioned above, although, I normally hear them mentioned in the order:'A', 'C', 'B', as in 30°/60°/0°. Don't forget to add in the depth gauge offset (typically 0.025 inches).

Part 2

As noted, some sets of angles will cut faster, but dull faster (racing chains versus fire wood chains). Some angles will cut better in different species of wood (soft wood versus hard wood). Even the power of the saw is a factor: a higher powered saw may be able to pull an aggressively filed chain in a way that a more modest powered saw can not.

Part 3

I have had a few factory reps tell me that the 'recommended angles' are intended for a general audience. in other words, STIHL, Oregon, etc., sell millions of chains, to millions of users, in dozens of countries, using hundreds of different saws, cutting thousands of different species of trees. While it is possible to optimize a chain to fit specific cutting situations, the manufacturers pick the 'best all around' settings for 'general use'.

So, if you are able to sharpen your chains

accurately and consistently, you should think of the recomended angle settings as 'starting points'. For many users, that is good enough. If you live on an oak plantation, and only cut red oak, it makes sense to try and optimize your chains for red oak. Same thing if you live on a Christmas tree farm. If you never know what you are going to cut (firewood scrounging, storm clean up, etc.), pick some general angles that work for you.

Experiment. Maybe try different angles with different brands of chains, or different saws. Some guys are stuck in a '

one-chain-on-one-saw' mindset, filing on the bar, and using a chain up before removing it. I like to think of my saws like a socket set:

power heads = ratchets (1/4", 3/8", 1/2" drive)

guide bars = extensions

chains = sockets (deep, 6 point, metric, etc.)

Choose what you need for the task at hand. You can have a bunch of different chains sharpened for different wood or cutting conditions (full chisel, semi-chisel, chipper, low kickback, etc.), such as soft wood, hard wood, frozen wood, dirty conditions, . . . .

If you prefer a golf analogy, approach each tree like a hole on the course, and select the appropriate powerhead, guide bar, and chain for the shot!

Part 4

In summary, don't sweat a few degrees that most guys probably can't measure very accurately anyways. Focus on getting each edge on each cutter sharp, and getting each cutter on a loop the same. If you deviate from the manufacturers' recommended angles, do it intentionally, and not due to lack of control. File guides and grinders help in this regard.

Philbert