Robnjay

Active OPE Member

- Local time

- 12:33 PM

- User ID

- 34186

- Joined

- Sep 2, 2025

- Messages

- 5

- Reaction score

- 7

- Location

- Victoria TX

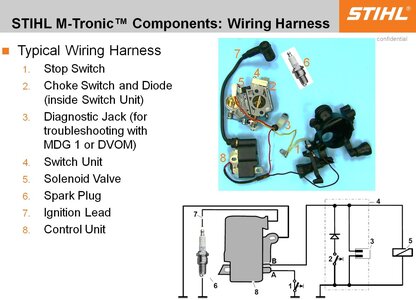

I’m trying to verify that I actually have a bad coil on this saw before I spring for the new part, here’s what I have done so far:

Replaced the solenoid with a new repair kit (white solenoid + orange filter)

Disconnected the 2 wire harness from the coil and measured both wires to ground - black is open until the lever is moved to the off (up) position, then shorted - red measures 36 ohms to ground. This is probably the resistance of the solenoid coil.

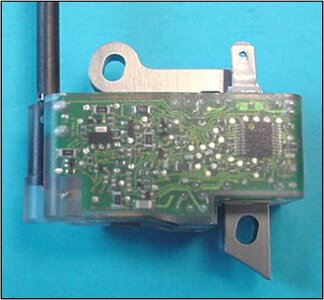

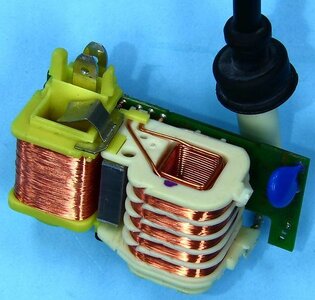

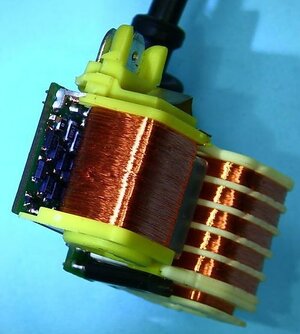

Measured the coil:

Primary is 1.87k ohms

Secondary is 2.4M ohms

Primary to secondary is 24.7k ohms

Zat 4 no spark…

Buy the part???

Replaced the solenoid with a new repair kit (white solenoid + orange filter)

Disconnected the 2 wire harness from the coil and measured both wires to ground - black is open until the lever is moved to the off (up) position, then shorted - red measures 36 ohms to ground. This is probably the resistance of the solenoid coil.

Measured the coil:

Primary is 1.87k ohms

Secondary is 2.4M ohms

Primary to secondary is 24.7k ohms

Zat 4 no spark…

Buy the part???