FergusonTO35

Here For The Long Haul!

- Local time

- 6:42 PM

- User ID

- 3545

- Joined

- Jul 9, 2017

- Messages

- 6,074

- Reaction score

- 14,685

- Location

- Boonesborough, KY

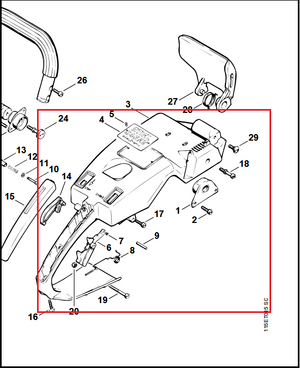

I'm the type who drills ball joints and tie rod ends to screw in grease fittings. Trying to resist the urge to drill grease holes in my Stihl bar tips.