- Local time

- 7:16 PM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,125

- Reaction score

- 29,505

- Location

- Dike, Iowa

Glad you got it going, maybe I’ll be at a g2g with you and I’ll bring my early 045 so we can see what the difference between the 07 and the next 75cc Stihl design of the 045.07 is back together and fully operational.

View attachment 460091

View attachment 460093

A few hiccups along the way. Muffler flange broke during some initial test runs.

View attachment 460094

I did manage to stick it back together with my flux core wire welder, not too pretty since the flange was brazed on to begin with but it held up fine through the further test runs.

View attachment 460095

The oiler was not working, very interesting system on this model.

View attachment 460096

There is a plunger that runs off a cam on the crankshaft (Item 19b) but rather than using that motion to pump the oil, it works a "ratchet" type mechanism on top of the oil pump (Item 3) to convert reciprocal into rotary motion. Eventually I figured out the spring (Item 21) was missing so the plunger was not moving back and forth as it should.

Mark

I use non chlorinated brake cleaner, any brand will do. Just DO NOT use chlorinated.Hi all, new here with my first Stihl MS 261C.

Just bought it second hand it looks good but it’s covered with a lot of dirt. I want to do the best I can before run it. I’ve removed the spring and the brake in order to clean around the clutch better (see photo). View attachment 460069View attachment 460070

Can someone tell me is there a specific way for assembling the brake because of this little piece inside (I think it was for splashing the oil).

And how to clean on the other side - it’s not gonna disappear only with compressed air

p.s. All the engine is also covered.

I had an 090 and it vibrated for sure, the 08 also does and the farm boss will give you the tingles alsoI expect the 045 would be much smoother in operation. Randy Mac used to saw the 090 would make your blood foam, just running this 07 on the test bench I am inclined to believe that.

Mark

Far as the piston circlip grove I think it could be done on a lathe but would be a lot of messing around. If you have a 4 jaw chuck you could machine a fairly tight rod or tube to run through the piston wrist pin bores. Put the piston in the 4 jaw chuck and use the rod to center and true the bores with tail stock. Then make a custom high speed cutter to make a groove. I’m sure this would work but would require a bit of messing around.Someone left me this 041 parts saw a few weeks ago. It felt like pretty decent compression so I thought I'd try to use the short block on my 041 Farm Boss with the plain aluminum bore since finding another chrome plated piston has proven to be very difficult.

View attachment 460161

However, I found the "flange" on the PTO side was badly cracked.

View attachment 460162

So, I decided to pull the cylinder and see about using the piston and cylinder on the FB. Plain aluminum bore on the left, chrome bore from the dirty saw on the right. From the marks on the castings, I am guessing the plain bore cylinder was indeed an OEM Stihl part not an aftermarket piece.

View attachment 460163

I was going to use the new piston so graciously provided by Powerstroke Cowboy, but ran into an issue when I discovered they forgot to cut one the the retaining grooves for the circlips. If anyone has a suggestion for cutting the groove with my very basic tool and skills I am eager to hear of it.

View attachment 460164

For now I will revert to my original thought of using the piston from the parts 041 and see if I can get this one together and running.

View attachment 460165

Mark

The big orange knob is for the oil output, one thing with the 041/051/075/076 is the oiler design gos into the case and uses some orings ro seal the bar oil out of case. If they ever start to smoke real bad it usually the o-rings on the pump that broke. Very cheap fix if it ever happens, not that you’d be running the farm boss for much anyway.With a little help from Chris pointing me in the right direction, I came up with a way to cut the groove for the circlip. I have a mandrel that closely matched the wrist pin size so I was able to secure that in the piston, the piston in the lathe, and modified a boring cutter to make the groove. Certainly not NASA tolerances, but good enough for a 1060's vintage chainsaw.

View attachment 460193

View attachment 460194

The saw now starts, runs, idles, and oils as it should, in fact the oiler is a bit too generous. Nice project to have done. The 041 is in reality a very simple saw to work on. I'm not sure what happened at the end of the video but you get the idea.

Mark

With a little help from Chris pointing me in the right direction, I came up with a way to cut the groove for the circlip. I have a mandrel that closely matched the wrist pin size so I was able to secure that in the piston, the piston in the lathe, and modified a boring cutter to make the groove. Certainly not NASA tolerances, but good enough for a 1060's vintage chainsaw.

View attachment 460193

View attachment 460194

The saw now starts, runs, idles, and oils as it should, in fact the oiler is a bit too generous. Nice project to have done. The 041 is in reality a very simple saw to work on. I'm not sure what happened at the end of the video but you get the idea.

Mark

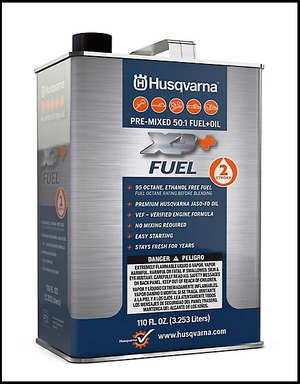

Until now, I didn't know that pre-mix fuel/oil was even available. Any idea where to buy it?Welcome to the forum, you can use "regular" gas from the pump mixed with oil, but my recommendation will be to use non-ethanol fuel if it is available and mix it with oil. It all depends on how often you will use the saw, if it is occasional use, the buying a gallon of premix fuel may be the best bet since it is non-ethanol and has additives that help preserve the fuel (keep it from breaking down as fast) and already has the correct mix you are looking for (50:1, 40:1...etc), it basically takes all the brain work out, you just pour and go. If you will be using the saw a lot, then mixing your own fuel will be more cost effective and you can use regular pump gas, however, non-ethanol premium is the better choice (ethanol can cause issues with the diaphragms in the carb). If you go regular or non-ethanol premium, then you can mix your own ratio, if it was my saw, I would use 40:1, but that is personal preference. Stihl's manual will list both 50:1 and 40:1 mixes, 40:1 just has a little more oil in the fuel.

People on the forum here have wide ranging opinions on oil type, fuel type and mix ratio numbers...they find something that works and stick with it. What you can do as an experiment is get a premix can of 50:1 and 40:1 and try them both and see if your saw respond better to one over the other. If it seems to run the same with both, then you know that either will work for your saw.

Lots of different hardware stores or ope dealersUntil now, I didn't know that pre-mix fuel/oil was even available. Any idea where to buy it?

Like @lehman live edge slab stated, they can be found in hardware stores and OPE dealers (usually anywhere at least Stihl and Husqvarna are sold).Until now, I didn't know that pre-mix fuel/oil was even available. Any idea where to buy it?

Vp sef is also good in fact harvest king brand is made by VP.Like @lehman live edge slab stated, they can be found in hardware stores and OPE dealers (usually anywhere at least Stihl and Husqvarna are sold).

A few places off the top of my head are Tractor Supply, ACE, Home Depot (at least shows on-line), O'Rileys, Murdoch's... They range in price from about $17.00 - $40.00 per gallon. I have used both Stihl and Harvest King and both work well, I prefer to use the Harvest King due to the cheaper price around $17-$20 depending on sales. I also use their 40:1. I have left this fuel in my weedeater (FS 91) over the winter for a couple of years and it fires right up each spring.

View attachment 460239View attachment 460240

View attachment 460241

Good grief...did they throw it against a tree while it was running??As a "bonus", the PTO side crankcase has a piece cracked off as well.

Almost looks like the ring location pin came lose allowing ring to spin and catch the end in a port.Jumping ahead a bit, I have an MS362C on the bench, very low compression. Piston actually looked O.K. through the exhaust. Not so good when it was all apart.

Looks to me like a ring broke.

View attachment 460716

Cylinder is trashed as well.

View attachment 460717

As a "bonus", the PTO side crankcase has a piece cracked off as well.

View attachment 460718

Mark

I’m sure it will work fine, how old of a 362 is it and what does he want to keep the work down to? I have a set of cases that are good needs bearings saw died from ingestion of sawdust and dirt because it completely wiped the nickosil off the jug. Could sent the case set with the rewind for the 040 that my lazy but hasn’t gotten out yet.Does anyone have experience with the kit from Saw Salvage AKA The Duke?

THE DUKE'S NIKASIL COATED PISTON AND CYLINDER KIT FITS STIHL MS362 1140 020 1205 47MM

Quality part, tool or accessory QUALITY NIKASIL COATED CYLINDER KIT FOR STIHL MS362 1140-020-1205 11400201205 Thank you for checking us out! In this listing you will find THE DUKE’S SAW SALVAGE high quality NIKASIL coated cylinder. We stand behind these cylinders and are convinced out their...www.sawsalvage.co

Given the other issues with this saw it looks like a $50 top end would be a good solution.

Mark