You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MCCULLOCH The official McCulloch thread

- Thread starter Frank bierce

- Start date

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

Yessir, it did.That’s some cool stuff! Nice score. Did the pm105 ever happen? Never seen one!

https://images.app.goo.gl/mqPtXjy84y89LEog8

Bigmac

Mastermind Approved!

- Local time

- 12:20 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,639

- Location

- Oregon

The ipl pic is like a 797 with sp105 engine and muffler cover, wonder if they made that configurationYessir, it did.

https://images.app.goo.gl/mqPtXjy84y89LEog8

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

Bigmac

Mastermind Approved!

- Local time

- 12:20 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,639

- Location

- Oregon

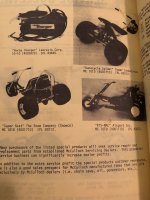

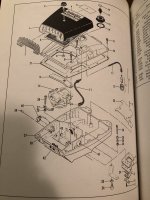

Cool! Wonder if anyone has one! I have seen a few 797’s with sp engines...wonder if it was one of those!that is interesting....this is what it shows here.

View attachment 213311

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

Al Smith

Here For The Long Haul!

- Local time

- 3:20 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

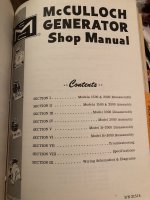

I've got both the big black 20 pound book and the micro fiche set .Problem is I have no way to copy the film into something I can post pictures from . Between the two is a lot of information if you can remember where it's at . Mc Bob sent me the CD he made too which is helpful .

I'm not sure exactly where the carb jet sizes are because I never fiddle with a fixed jet carb ,Really dislike them .In addition I have no idea where a person could even find them these days . It isn't like you can trot on down to your friendly local McCulloch dealer because he retired with the village blacksmith .

I'm not sure exactly where the carb jet sizes are because I never fiddle with a fixed jet carb ,Really dislike them .In addition I have no idea where a person could even find them these days . It isn't like you can trot on down to your friendly local McCulloch dealer because he retired with the village blacksmith .

- Local time

- 2:20 AM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,131

- Reaction score

- 29,586

- Location

- Dike, Iowa

Al Smith

Here For The Long Haul!

- Local time

- 3:20 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

Well no doubt about it you have stuff you most likely will never see any where else .Well done .

Yukon Stihl

Pinnacle OPE Member

- Local time

- 12:20 AM

- User ID

- 508

- Joined

- Jan 11, 2016

- Messages

- 1,316

- Reaction score

- 5,172

- Location

- Great White North

So after a wild spring summer and fall i am so looking forward to winter.

I have my boiler heating my house,so my boiler building is warm and my crates of projects are calling.

First up is my Mac 70 that is in a saw body.It was from an old logger from Haines Alaska.It was his play saw for competitions.I got it after it had been sitting for years.The stuffer plate had lots of corrosion so i took the saw apart for cleaning and new bearings and seals.

The seals i got for the points end are double lip seals.So my question is should i still put two seals in on that side.

Plus any torque specs for the rod bolts? or anything else that is important? I have 24 needle bearings for the rod is that the correct amount? Thanks

I have my boiler heating my house,so my boiler building is warm and my crates of projects are calling.

First up is my Mac 70 that is in a saw body.It was from an old logger from Haines Alaska.It was his play saw for competitions.I got it after it had been sitting for years.The stuffer plate had lots of corrosion so i took the saw apart for cleaning and new bearings and seals.

The seals i got for the points end are double lip seals.So my question is should i still put two seals in on that side.

Plus any torque specs for the rod bolts? or anything else that is important? I have 24 needle bearings for the rod is that the correct amount? Thanks

Al Smith

Here For The Long Haul!

- Local time

- 3:20 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

I can't talk about a kart engine but on the 125's it shows two seals one lip in one lip out .Positive seal both directions .That said I've heard from people who do a lot of them say they have used one double lip and get the same results .

Yukon Stihl

Pinnacle OPE Member

- Local time

- 12:20 AM

- User ID

- 508

- Joined

- Jan 11, 2016

- Messages

- 1,316

- Reaction score

- 5,172

- Location

- Great White North

I thought i had a Mc 20 Kart engine that's what it said so i never looked close at it.

Turns out it has numbers stamped in the block not Mc70 like the other one.

66019 and 2085

Turns out it has numbers stamped in the block not Mc70 like the other one.

66019 and 2085

- Local time

- 12:20 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,743

- Reaction score

- 67,062

- Location

- Coastal Oregon

So after a wild spring summer and fall i am so looking forward to winter.

I have my boiler heating my house,so my boiler building is warm and my crates of projects are calling.

First up is my Mac 70 that is in a saw body.It was from an old logger from Haines Alaska.It was his play saw for competitions.I got it after it had been sitting for years.The stuffer plate had lots of corrosion so i took the saw apart for cleaning and new bearings and seals.

The seals i got for the points end are double lip seals.So my question is should i still put two seals in on that side.

Plus any torque specs for the rod bolts? or anything else that is important? I have 24 needle bearings for the rod is that the correct amount? Thanks

24 Needles is correct. Here's some torque specs I got from one of the guys over at rearviewkarts.com:

torque values

Coil/lamination Screws ------------55-60 inch pounds

Condenser screws ----------------30-35 inch pounds

Con rod - mc49 mc 91 -------------105-110 inch pounds *

Con rod - mc101 ---------------90-95 inch pounds *

*a master mc builder told me told that 101 rod bolts with 85-90 inch pounds and red loctite is bullet proof

and torquing to 110 results in cracked caps.i myself do 85-90 inch pounds

Crankcase End Cover Screws --------60-65 inch pounds

Crankcase Bottom screws -------- --95-100 inch pounds

Cylinder Head Screws -------- --55-60 inch pounds

Exhaust Header Screws -------- ----55-60 inch pounds

Fan Housing Screws ----------------55-60 inch pounds

Flywheel nut ----------------------300-360 inch pounds

Spark plug -----------------------216-264 inch pounds

Clutch Nut ------------------------ 260-300 inch pounds

Bigmac

Mastermind Approved!

- Local time

- 12:20 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,639

- Location

- Oregon

Getting some saw ready for a 50” bar shootout, and my trusty sp125c was missing in the top end but idled great, tried to tune it a little and nothing...then it died...checked spark, nothing! Pulled the recoil checked the wires, looked good, so I pulled the flywheel and checked the points, all good, then put on a spare coil and it was sparkling again! Points coil down! Put it back together and a new plug, Golden! Need to put a carb kit in the 797 and it should be ready too. Going to try them against a homelite 750 and husky 2100cd hopefully it all works out

- Local time

- 12:20 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

What a lineup!!Getting some saw ready for a 50” bar shootout, and my trusty sp125c was missing in the top end but idled great, tried to tune it a little and nothing...then it died...checked spark, nothing! Pulled the recoil checked the wires, looked good, so I pulled the flywheel and checked the points, all good, then put on a spare coil and it was sparkling again! Points coil down! Put it back together and a new plug, Golden! Need to put a carb kit in the 797 and it should be ready too. Going to try them against a homelite 750 and husky 2100cd hopefully it all works outView attachment 213600View attachment 213601

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 8

- Views

- 1K