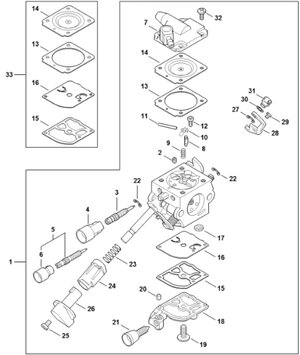

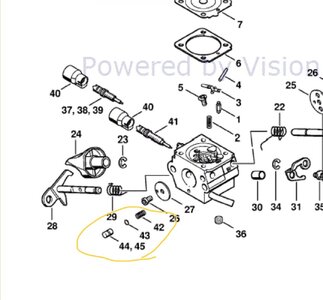

I have a BR450 that I purchased new in 2018, which has performed flawlessly until recently. I am a homeowner who uses it once a week during the summer months, after mowing, and multiple times during the Fall leaf season. I do not believe it is "worn out", like piston rings, crankcase seal, etc. I've always ran 93 octane gas, mixed at 32:1, with the recommended amount of Sea Foam in the mix to keep it clean. I've kept a clean air filter in it. The issue is that, from cold, it will crank up and run as normal, but after 5-10 minutes of wide open throttle blowing, it will quit running. I checked the screen in the muffler, and it is clean. I replaced the fuel filter and gas tank vent. I replaced the coil and the spark plug. None of these things helped. I've removed the plug during these events, and it's dry. My gut feeling is that it's the carburetor, for whatever reason not keeping fuel in the "bowl". I replaced the carburetor, and it ran as normal for a couple of weekend uses. Thinking the problem is solved, but no, the next use it died again after probably 10 minutes. When it does this, it might re-crank once or twice, but will not throttle up wide open, and eventually it won't crank at all. Fuel can be moved using the priming bulb as normal. There is no debris blocking air flow and nothing obstructing the cooling fins on the cylinder, so I don't think it is an overheating issue. The fuel line itself is about the only thing I haven't replaced, but it is supple and looks ok. Any advice is appreciated.