Time to dredge this thread up again! I finally have a need to put my 044 to work cutting some charity firewood and I need to get this pump modification done first as these trunks are now dry and will soak up oil like a sponge.

Here is the new control bolt as listed in the 2004 MS460 for t he Rescue Saw (H.O Oiler)

Here is the original control bolt on the left. HO control bolt on the right. The flats on the end of the bolts are orientated the same (down). Yes, they are different.

The first order of business was to measure the piston travel in both the min an max settings of the control bolt.

044 oil pump as found (unmodified pump piston)

Min travel - .014"

Max travel - .032"

Next I swapped out the control bolt only

044 oil pump ( H.O. control bolt & unmodified pump piston)

Min travel - .009"

Max travel - .031"

Interesting outcome... According to these measurements changing the control bolt only should have zero increase in oil output!

For those that saw an increase by taking the pump apart and changing out just the control bolt probably just ended up cleaning out some crud from the pump. I have seen this before on at least one 026/MS260. The pickup screen in the oil tank is coarse enough to let some sawdust and crud through it. Most of this will get flushed out to the bar but some will build up in the pump and eventually reduce piston travel and reduce oil output.

So the max travel with the original piston is about .032" (0.8mm) Sound familiar?

Guess what else measures .032"? If you measure the difference in the high and low points of the cam on the piston you get... .032"! So the cam on the piston ultimately limits the maximum piston travel.

So how does the control bolt fit in?

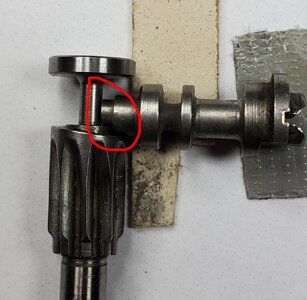

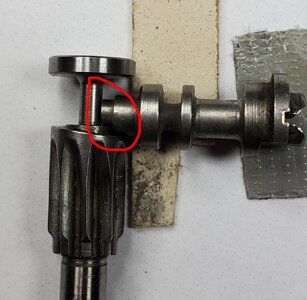

Here is the orientation of the control bolt at max flow with the unmodified pump piston. Note that both cams on the control bolt mesh with corresponding surfaces on the piston (circled in red).

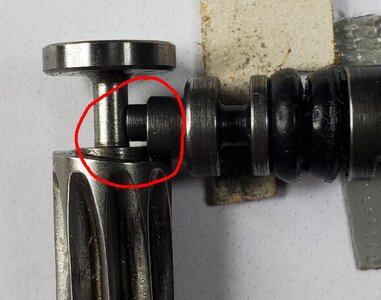

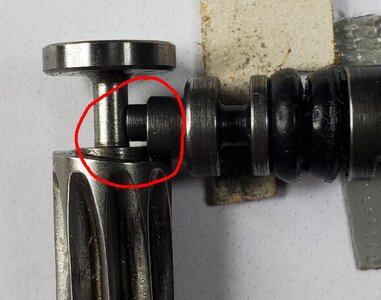

Here is the HO control bolt and the unmodified piston. Note the air gap between the small cam on the HO control bolt and the stop on the piston. The only way to make these match up is to machine the ramp on the piston as others have done before.

I used a 3/16" round diamond hone in my dremel at the lowest speed and followed up with a flat #320 diamond hone. According to my measurements I took off about .015 max but it may not be perfectly flat as it should be. It looked like the surfaces mated well outside the pump.

So I reassembled the pump and did some final measurements:

044 oil pump (HO control bolt & modified pump piston)

Min travel - .009"

Max travel - .040" (1.0mm)