bmwpowere36m3

Well-Known OPE Member

For a MS192T, different saw...

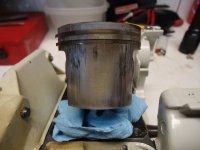

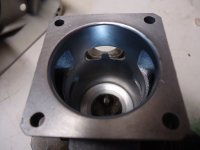

Piston is a little scored there in photo #1. While saw is apart, you may want to pull the jug and check it too.

It happens and isn't always a bad sign. Usually with the piston rotating near TDC. Pull the plug and see if the sound goes away. But I only accept this after knowing all inside was inspected and checked out OK.That's the next step after I get the crankcase cleaned up first. Any comments on the flywheel "clicking"?

Is the flywheel clamped on tight?

If it's loose the key can tick in the keyway as there will be a touch of clearance

Don't forget to pull the oil pump and replace the oil pickup hose that goes into the case

These are often behind oil leaks during storage

It happens and isn't always a bad sign. Usually with the piston rotating near TDC. Pull the plug and see if the sound goes away. But I only accept this after knowing all inside was inspected and checked out OK.

You need a piston. That fuel line looks like the newer MS360 line to me, or maybe not-it does look thinner. The flat portion on the grommet goes forward. You may have to open the tank inlet for it.

If it were my saw, I would be cracking the case and cleaning it up, changing the bearings, crank seals, case gasket, piston and rings, new OEM piston wrist pin bearing, new spark plug, new oil pump suction hose, new clutch, new clutch drum, new bar and chain and a serious muffler mod.

I only change the fuel line if its gone hard or soft and is leaking.

The muffler on these saws is one of the worst restrictive mufflers I have seen with a double baffle.

Either cut out the baffle, or remove the plate with the holes in it on the front cover to help flow.

If noise is not an issue, get rid of both. I can guarantee you will get a 10 to 20% power boost with just opening up this restrictive muffler.

I recently rebuilt an 034 super and with the stock muffler it felt strangled and cut like a saw 10cc less.

The guy who bought it wanted it left stock as he thinks if I get it breathing better it will blow up.

Its a great saw. half a job wont last another 30 years. If you leave one old part in there it will fail eventually

Just my opinion.

When I have a saw that's a keeper, I would rather spend a little bit extra on parts to do a full rebuild and know its completely overhauled than be using it thinking...... geez I hope that old case gasket I left in there holds out.