two4spooky

Super OPE Member

- Local time

- 12:02 AM

- User ID

- 4851

- Joined

- Dec 22, 2017

- Messages

- 195

- Reaction score

- 672

- Location

- Southeast

Rhetorical question: The answer is "YES!!!" I have an issue regarding axes

Last edited:

"2 below 0". You Northerners are crazy. We are hitting mid-20's and teen's with wind chill even lower here in the South. I want to crawl in a hole and hide with this coldness. Too much cold for me to be outside, employer excepted and required. Kudo's to you!!! I would not make it at those temps. I have no interest in anything done outside at these temps. I prefer my basement till it warms up2 below 0 here in Iowa this morning but no wind so I got some cutting and splitting done. Had two Cherry blow overs that have been off the ground, barkless and drying. Cherry usually splits easily and this was no exception. The Keen Kutter is a 5 lbs felling axe and the smaller one is a 3.5 lbs Hults Bruk that I rehung (House Handle Co) with hitting wedges in mind. Neither work as well for splitting as the Fiskars X25 but to be fair they aren’t really designed for it. This wood will go right in the boiler. Already tossed the root balls in.

All love. The effort given here to the Dragon Slayer head and it's replacement is impressive. The results you have splitting are awesome. ***Question: How will the welding and grinding affect the hardness/tempering of the head's steel? How will you measure the effect?*** How will you change the hardness in the steel Rc(hardness) at the edge? Seriously curious. Especially the cutting edge. Much respect here from a less experienced user with much less knowledge. Kudos to WilhelmI am working on converting a non DragonSlayer ax head to at least close to the performance of my DragonSlayer ax.

View attachment 447969

View attachment 447970

A whole bunch of welding up the other ax heads cheeks as they were concave, and hours of grinding so far.

I am welding up surface impurities & holes with my little flux core welder, not too bad I guess.

View attachment 447971

I am not impressed by the cheek weld job a coworker of mine did.

Those beads are cold welds!

View attachment 447972

This ax head I am modifying lost any temper it may have had.All love. The effort given here to the Dragon Slayer head and it's replacement is impressive. ***Question: How will the welding and grinding affect the hardness/tempering of the steel? How will you measure the effect?*** How will you change the hardness in the steel Rc(hardness) at the edge? Seriously curious. Especially the cutting edge. Much respect here from a less experienced user with much less knowledge.

Impressive. Kudos to your use and experience. My use, patience and expectations are much less. My "hat is off to you". Carry on with best wishes. Said in a thoughtfully, sinceriously but "man-This ax head I am modifying lost any temper it may have had.

The steel feels soft under the 9" angle grinder wheel.

Worst case scenario, I will cut off part of the blade and weld on a 12.9 grade bolt. That way I know I have alloyed steel at the blade that can be quenched.

How will I determine hardness?

Simply by using it in the same manner as I do my DragonSlayer.

I split rounds into manageable slices on the ground (back yard lawn), as such contact with dirt, sand, stones & gravel is inevitable - if the modded ax head blade damages quick it is too soft.

Curious how good the bolt worked out for the ax edge. Is the steel too soft or too hard or too brittle?My attempt of restoring some blade life on a decades old hatchet by welding a 12.9 grade bolt piece to the ground back blade.

View attachment 447948

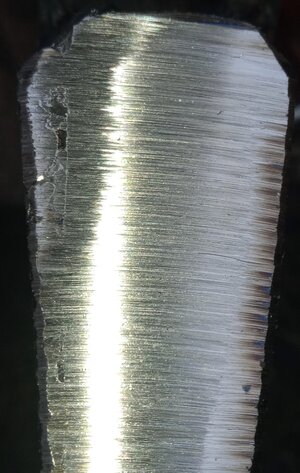

After a fair amount of grinding it came out to this.

Need to use it and see whether I have to try quench the blade or not.

View attachment 447949

View attachment 447950

View attachment 447951

I don't know yet, I'd have to quick/extreme test the blade.Curious how good the bolt worked out for the ax edge. Is the steel too soft or too hard or too brittle?

I wouldn't torture test it. Just use in wood and see what you think.I don't know yet, I'd have to quick/extreme test the blade.

I smacked through and into a couple dry turkey oak knots and the renewed blade didn't mind.

Any suggestions how to torture test the hatchet blade?

Preferably without actually risking severe damage.

Smack it into aluminum, copper, brass, a softer steel bolt?

@davidwyby , what do You think?

I don't know yet, I'd have to quick/extreme test the blade.

I smacked through and into a couple dry turkey oak knots and the renewed blade didn't mind.

Any suggestions how to torture test the hatchet blade?

Preferably without actually risking severe damage.

Smack it into aluminum, copper, brass, a softer steel bolt?

@davidwyby , what do You think?

Husqvarna flat file is not skating as it does on my DragonSlayer ax, but doesn't dig in either.Test it with a file. Too soft and the file will dig in easily.

My thoughts exactly. A little time and use will tell you.I wouldn't torture test it. Just use in wood and see what you think.

Didn't you say you had a semi-local blacksmith, made swords but no axes? Maybe he would be able to temper the whole head?Husqvarna flat file is not skating as it does on my DragonSlayer ax, but doesn't dig in either.

You have been keeping track haven't You?!Didn't you say you had a semi-local blacksmith, made swords but no axes? Maybe he would be able to temper the whole head?