South_Prairie_Saw

Well-Known OPE Member

- Local time

- 7:12 PM

- User ID

- 35045

- Joined

- Dec 22, 2025

- Messages

- 43

- Reaction score

- 136

- Location

- Puyallup, Wa

Whoops forgot, dial test indicator is pretty commonCo-axial or for me it would be an Interapid 312-B

Whoops forgot, dial test indicator is pretty commonCo-axial or for me it would be an Interapid 312-B

I don'[t know chit about cnc machinihng but it is quite interesting. I can't find the vidja now and wouldn't post it anyways, it was just so I could kind of peak into that world and see what goes on was all. It may really be all super accurate and all that it's claimed to be, I just don't know how one goes about programing these and if it's truly doing good or not. In this case it measured the flat part of the four corners of the base and four spots on the bore fairly shallow. I just can't picture how the band cut can be true and concentric when the cylinder was tilted to be flat.I’d be curious to see this vid and the setup. While you’re 100% correct in dialing in the bore to be straight. Did they hit the base, or the holes for the screws? That would def create some problems if they’re going off a cast profile for precise location….

A CNC mill needs at least “zeros” in three directions. X and Y (bore centerline most likely) but I’d think that they’d have to pick up the holes in cylinder to help align it in the proper orientation. Z is depth. Not sure if they’re setting depth from the base or the band, depends on how it was programmed.

I should again say I’ve never ported cylinders or down saw work in a lathe. BUT I’ve spent 15 years in the CNC world and still work on the carbide side as of right now. I’d love to see it work but the machine is only as good as the person behind it

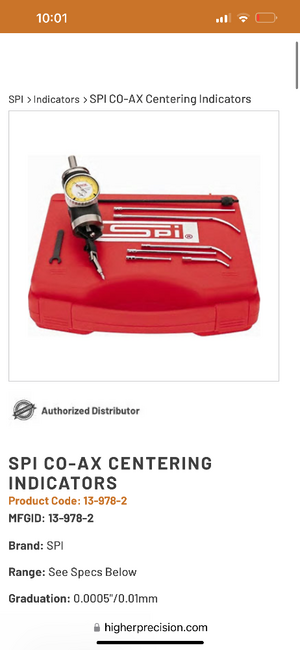

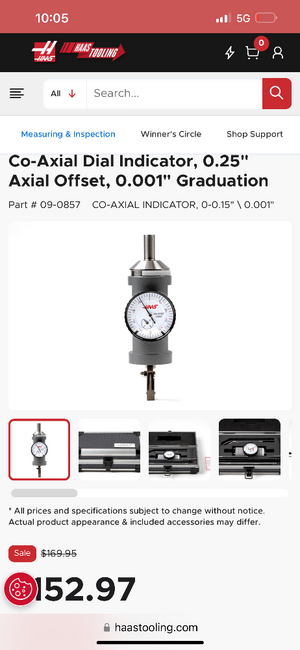

I’d be comfortable with this indicator, SPI isn’t top of the line but not chit either.I have common dial test indicators. Some make of co-ax is what I'm asking about.

I'm never gonna get over adult men wearing sleep wear in public! Or sweat pants ,unless you're leaving or going to the gym.

I don't really give a *s-word about what other people do, but shame seems like a thing of the past.

Chainsaw content on YouTube is toughwhile BBR isn’t all too far from my neck of the woods, there’s so much talking and not much else. Seems like an alright guy but yeah a little much for me. I do like Gordy’s channel as he has some variety and they just get down to it and cut. Lot of “influencer” types and they aren’t for me. YouTube is great, just have to find stuff worth watching but again, a lot of these guys have an ego

I get what you are saying which is one of the reasons I spend less and less time on this forum reading comments.I'd feel like I was 13 standing in line at the mall with an issue of Teen Beat magazine waiting to get an autograph if I watched these people...I have to work, I don't have the time anyway.

People b!tch about these people and how corny they are....so don't watch them - problem solved. My least favorite thing about the time we live in is that no matter how retarded you are you can have a worldwide audience...and then an over inflated sense of self-importance because people equally as retarded participate. According to this piece of garbage phone I have the internet gets 14-21 minutes a day of my attention, I have no doubt I'm better off for it.

I think I have some form of retardation where I can't pay attention to stupid sh!t for more than 30 seconds. The only time I click on a chainsaw video is when I'm on the *s-wordter and 30 seconds in I feel my testosterone go down and my embarrassment for myself going up for even giving it that 30 seconds.

I don't have time to worry about what other people do, I wouldn't care anyway..I was never much of a follower to begin with.

Not long ago, I was looking for tips on fixing bar oil leaks. One video in particular, the guy talked for about a minute, then spent a few minutes getting the clutch cover off ... I gave up. That was a week ago. I dare hope that he's found the oil pump by now.I don't think it's retardation, or maybe it is and I have it too. I do find some videos useful, if I'm looking for specific information, but would really prefer to read a written document. That way I can easily skip over non-pertinent information. But I really have little patience for most videos out there, especially the "how to" videos where the presenter doesn't have a clue, or the ones that show someone making a brief statement of some type then the presenter spends 30 minutes telling you what you just watched and how you should feel about it. BS.

Last week a video was posted here that had a neat machine at work in it, but it was overshadowed by foolishness by the "star" of the video. I can't stomach that, especially knowing they're making money acting ignorant. No thanks.

Some videos can be helpful especially when working on a saw I am unfamiliar with or took apart without documenting how things came off. I can care less about ramblings, and really hate when they get to a critical take apart/put together spot and then cut and come back and say "well, that wasn't important so I did it off camera..." There are definitely certain content creators I avoid and there are a few good ones (old school) that actually step through a repair or modification without much fanfare or unnecessary chatter.I do find some videos useful, if I'm looking for specific information, but would really prefer to read a written document.

...really hate when they get to a critical take apart/put together spot and then cut and come back and say "well, that wasn't important so I did it off camera..."

Well, as far as the CNC part goes, I just happened to come across a vidja from another feller doing the same thing to the same saw. (seems to be trending) I was fairly curious on how the machine was set up and cut etc. compared to a lathe that's now old and obsolete, yeah right.Anyways, what I took notice of first was that the placement of the "index" tool was quite unique to me, in that it only took four points from the top of the bore in a cross pattern and four points from each corner of the base. The setup was off .005" on the base and reset itself to true the base up and line up the bore. Which is quite different from myself of aligning the bore and thus truing the band and base to the bore. To me it's kind of like a gunsmith doing an action job to the outside of the barrel and not the bore where it counts. Which kind of negates the accuracy claims of the machine if it's not used properly. So, at the end of the day, it all comes down to how you use it for it to be beneficial to a harmonious outcome.

It did do the exhaust port, not the transfers, those were done by hand as well as all the chamfering and polishing. Which probably took longer than the entire set up and marching combined in the CNC, so it is a time saver vs a lathe. It(the cnc) is also making parts all night being fed by a robotic arm to help make it pay, which is something I could never see doing with my "One at a timing".

Here's a vidja I did a couple years ago showing how I align the bore to cut the squish band. Y'all can decide for yourselves what you think is right.

They designed it, cast it and machined it. If it was as simple as writing a program and having some flunky put it on a fixture and push the button, wouldn't they be doing it at the factory?I’d be curious to see this vid and the setup. While you’re 100% correct in dialing in the bore to be straight. Did they hit the base, or the holes for the screws? That would def create some problems if they’re going off a cast profile for precise location….

A CNC mill needs at least “zeros” in three directions. X and Y (bore centerline most likely) but I’d think that they’d have to pick up the holes in cylinder to help align it in the proper orientation. Z is depth. Not sure if they’re setting depth from the base or the band, depends on how it was programmed.

I should again say I’ve never ported cylinders or down saw work in a lathe. BUT I’ve spent 15 years in the CNC world and still work on the carbide side as of right now. I’d love to see it work but the machine is only as good as the person behind it

Close out your browser and flush your history/cookies and it will start YouTube's algo anew. Unfortunately it also wipes the videos you generally want to see pop up like chainsaw videos or how-to-repair videos...etc.with no way to reset.

"Slime, rot, rats and snot" has been replaying in my head for 45 years."Your mind is totally controlled

It has been stuffed into my mold

And you will do as you are told

Until the rights to you are sold."

Frank Zappa, "I am the Slime"

Don't forget to like and subscribe!

UhhhhhgClose out your browser and flush your history/cookies and it will start YouTube's algo anew. Unfortunately it also wipes the videos you generally want to see pop up like chainsaw videos or how-to-repair videos...etc.