Kenmore was good stuff. I had a jc Higgins shotgun. Have a bunch of craftsman tools and one craftsman 3.3 chainsaw. It's a poulan 3300 and it's a very good saw. I like it.

Craftsman used to make good stuff. But times have changed I think.

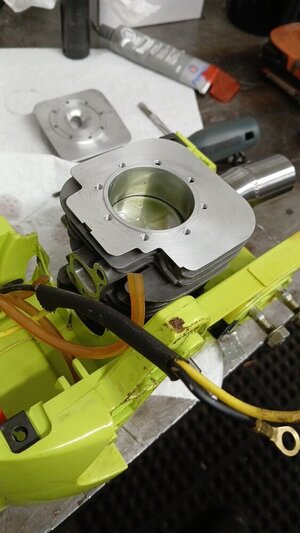

This wild thing is pretty well ready to start, waiting on the motoseal.

The aftermarket jug was not the best but we will see how it runs. I have 2 other cylinders I havent touched yet. Tunneled out the lower transfers quite a bit, had to tig up the jug. Way more than I normally would go. Didnt touch the piston. Couldnt go lower with the jug or it would free port. The transfers were at 121, so I raised the exh to 99. I opened up the rest of the transfers a little and swept them back more. Intake was 64, haha. Took it down to 73.

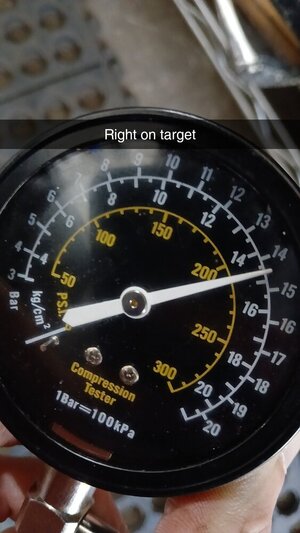

Cylinder head was cut off a strato saw jug. Head is sealed with eight 4mm bolts, with a 0.040" copper wire in a groove about 8 thou proud. It has about 50 percent squishband, depth mics say squish should be around 17 thou, if my copper wire copresses the full 0.008". Well see, havent bolted the head on for good yet.

Might build a tuned pipe. If so, ill raise the exh to 90. Transfers would be good where they are at. I see questions about this (port timing saws vs bikes) and there are a few reasons you want a long blow down and a 90 deg exhaust:

-When the positive part of the sonic wave returns and jams the air fuel transfer back into the port, that wave bounces off, travels the pipe and combines with the next pulse harmonicslly making a stronger pulse. You want the port open and closed the same duration. This is why piped 2 strokes have a 90 deg open, or even a few deg higher.

-Its desireable to have a long blow down, and good flowing transfers with a pipe. Main reason for this is so the transfers are closed when the wave returns. You want to jam the charge into the cylinder, but not back down the transfers.

People say design the pipe around the ports. And this is true to an extent, but there are ballpark ideal port numbers with a pipe just like a can, and they dont look alike for various reasons.