You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post up your ported cylinder Artwork

- Thread starter Chris Zautner

- Start date

farminkarman

I like the red & black ones

- Local time

- 3:18 PM

- User ID

- 13535

- Joined

- Aug 17, 2020

- Messages

- 5,027

- Reaction score

- 29,062

- Location

- Neenah Wisconsin

- Local time

- 4:18 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,593

- Location

- Strong Island NY

- Local time

- 4:18 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,593

- Location

- Strong Island NY

- Local time

- 3:18 PM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

Nice work fellas.

- Local time

- 4:18 PM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

Everytime I come on this thread it reminds me of how much of a hacksmith I am. I need to get better......

661

661

Attachments

Last edited:

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

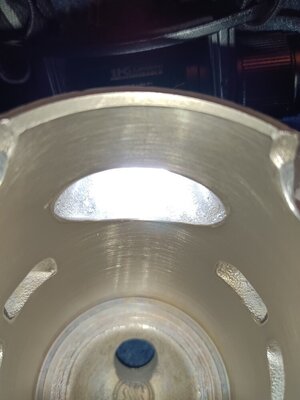

I lost some confidence in continuing this one because of the squish band being so uneven.

I ended up just widening the exhaust and cutting .010 of the base.

There's also a casting defect in the cylinder wall. 500i

I ended up just widening the exhaust and cutting .010 of the base.

There's also a casting defect in the cylinder wall. 500i

Attachments

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

I lost some confidence in continuing this one because of the squish band being so uneven.

I ended up just widening the exhaust and cutting .010 of the base.

There's also a casting defect in the cylinder wall. 500i

Attachments

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

Removed a little from the band and epoxied the intake. Still need to set it's fine intake numbers.

Attachments

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

Removed a little from the band and epoxied the intake. Still need to set it's fine intake numbers.

New numbers to

Exhaust 100

Primary transfer 121

Secondary transfer 124

Intake 80

Attachments

Ketchup

Epoxy member

- Local time

- 2:18 PM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,517

- Reaction score

- 8,470

- Location

- Colorado

I lost some confidence in continuing this one because of the squish band being so uneven.

I ended up just widening the exhaust and cutting .010 of the base.

There's also a casting defect in the cylinder wall. 500i

Was the squish band damaged in some way?

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

Was the squish band damaged in some way?

No, it just needs cut down, I didn't have the time last go around to cut it. Though after I did that 661 cylinder and got that saw back together I started taking apart the 500. So tomorrow evening I'll probably do that.

Edit: if you meant that 661 cylinder and not the 500, yes it did have some damage, it was a second hand cylinder with pinging at the top*

MG porting

Pinnacle OPE Member

legdelimber

Pinnacle OPE Member

What are you folks using as a release agent to keep the inner form/barrier or piston from sticking to the epoxy

Just a thin wipe of oil, car wax, cooking spray, or....?

I'd like to fill the large gaps between the transfer caps (to cylinder cut out) of a redmax blower ebz8500, but of course I don't want to accidentally glue the caps to the cylinder.

Just a thin wipe of oil, car wax, cooking spray, or....?

I'd like to fill the large gaps between the transfer caps (to cylinder cut out) of a redmax blower ebz8500, but of course I don't want to accidentally glue the caps to the cylinder.

- Local time

- 4:18 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,522

- Reaction score

- 150,420

- Location

- East Jordan, MI

I use metal foil tape on the inside of the boreWhat are you folks using as a release agent to keep the inner form/barrier or piston from sticking to the epoxy

Just a thin wipe of oil, car wax, cooking spray, or....?

I'd like to fill the large gaps between the transfer caps (to cylinder cut out) of a redmax blower ebz8500, but of course I don't want to accidentally glue the caps to the cylinder.

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

I use masking tape, then it will sit ever so slightly proud. Inside the cylinder, it can be easily removed with a slight use of a razor blade then some 220grit lightly applied the 220 won't harm the plating. (Unless you start using excessive force)What are you folks using as a release agent to keep the inner form/barrier or piston from sticking to the epoxy

Just a thin wipe of oil, car wax, cooking spray, or....?

I'd like to fill the large gaps between the transfer caps (to cylinder cut out) of a redmax blower ebz8500, but of course I don't want to accidentally glue the caps to the cylinder.

- Local time

- 4:18 PM

- User ID

- 9566

- Joined

- May 24, 2019

- Messages

- 653

- Reaction score

- 2,082

- Location

- WV/NC

MG porting

Pinnacle OPE Member

Old piston with a light coat of grease.What are you folks using as a release agent to keep the inner form/barrier or piston from sticking to the epoxy

Just a thin wipe of oil, car wax, cooking spray, or....?

I'd like to fill the large gaps between the transfer caps (to cylinder cut out) of a redmax blower ebz8500, but of course I don't want to accidentally glue the caps to the cylinder.

Similar threads

- Replies

- 20

- Views

- 1K