Dieselshawn

Pinnacle OPE Member

- Local time

- 1:55 AM

- User ID

- 804

- Joined

- Feb 6, 2016

- Messages

- 541

- Reaction score

- 3,001

- Location

- Southern Ontario, canada

My 660’s exhaust port is still clean since I bought the saw years ago.

Just checked it a few weeks ago.

View attachment 302363

One of Mastermind’s work.

Great saw.

You run Yamalube 2R ?

is that why a 372xp has a 044 beat?A theory of mine.....and chock full of exceptions.

A two port transfer setup needs less blowdown than a four port arrangement.

I think that it's because the two port deal is lazy....has less velocity. The shorter blowdown gives it a head start on movement.

is that why a 372xp has a 044 beat?

You polished that exhaust port?Looks like it has a little bit of time on it.

You polished that exhaust port?

Are you still using this on your 660?Yes I do. At 32:1

I was just "sent to the corner" from the Show off mufflers thread back here, w/ dunce-cap, so am glad to find another dorkLet’s drag this thread out again…

May I ask why you're distinguishing "small saws"? I hear this a lot, the concept of different approaches on a 25cc versus a 90cc, and it kinda confuses me (in all aspects) because so far as I have ever been able to objectively determine, a 90cc is simply a linearly-correlated scaled-up version nothing more/nothing less, but this would mean:View attachment 319979

I’ve been into several newer small saws recently and keep finding these steps in the exhaust roof. I’ve been trying to figure out why this is so prominent in newer designs. This is the V3 201t, but the 550mk2 I’m messing with now has it as well. 2511t also has it (though that one is a 90 degree exhaust so who knows?)

I just finished reading this entire thread again (round 4?) and now I have a theory. I think the step helps with the end of the scavenge cycle.

As the piston drops so does exhaust pressure. Fresh charge is flowing in from the transfers and the scavenge loop is pushing exhaust out starting at the back half (intake side) of the piston crown, then the intake side cylinder wall, then the combustion chamber and then out the TOP of the exhaust port. There is a low flow area on the exhaust side of the piston crown and the bottom of the exhaust port. Most piston wash patterns show a carbon area closest to the exhaust port because this is the lowest flow part of the scavenge loop. Here’s an imperfect example.

View attachment 319980

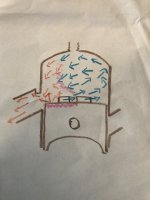

My theory is that the exhaust gasses are still expanding in that low flow zone. The step in the exhaust roof becomes more available as the piston drops and allows more of the exhaust gas to get swept away. Here’s a crap drawing:

View attachment 319981

The idea seems to work with EPA style engines that want to keep as much unburnt fuel inside the saw as possible. But it also makes more power to clear all the exhaust with new fuel so it may be helping emissions and performance.

Kind a long think-out-loud, but maybe folks will find it interesting. Or find flaws in the theory.

Are you still using this on your 660?

@Mastermind what ratio would you suggest be used in that kit-660? Would you say the same ratio for the g660? (can't stop myself from saying Thanks again, appreciated/appreciate it more than you know and I suspect my posts give some idea)

I was just "sent to the corner" from the Show off mufflers thread back here, w/ dunce-cap, so am glad to find another dork

May I ask why you're distinguishing "small saws"? I hear this a lot, the concept of different approaches on a 25cc versus a 90cc, and it kinda confuses me (in all aspects) because so far as I have ever been able to objectively determine, a 90cc is simply a linearly-correlated scaled-up version nothing more/nothing less, but this would mean:

- porting #'s would be the same (which they are....so far as I know)

- relative sizing of jug//carb//muffler should all be constant, and

- air//fuel ratio, and oil-% in the fuel, would be constant (here people almost unanimously say to use higher oil% on larger displacement....also on "milling saws"...this confuses me as I'd think there'd be "optimal" and anything more is insufficient lubrication, anything more is waste/carbon, I mean the "final consideration" is a saw working at 'full heat' and full-throttle, can't understand rationale for changes here due to nothing more than displacement, I wonder if the motorcycle/race-bike world sees this "sliding scale" of oil%, too?)

Feel very silly not having seen that step on my 2511t, though to be fair I didn't remove the jug I only flared the last 1/4"...but you mention its right-angle entry to the muffler, I saw that as "an unfortunate artifact of the design" not intentional, however I'd argue that the "step" you're illustrating - being it's at the entry to the port - is a fully separate 'feature' from that 90deg turn into the muffler. I will say I found 2 things super anomalous on the 'exhaust system' of the 2511t:

#1 - that super long, non-diverging / straight exhaust port.... Saw OEM's had been moving to larger exhaust-flanges IE more angle/divergence in the exhaust port (the 880 flange is like 50% larger than the 088's), I figured since we don't use pipes that we're basically utilizing the port itself as "header" into the muffler("expansion chamber") and having a diverging angle - especially increasing angles of more & more divergence - before entry-into the belly of muffler is absolutely beneficial (Jennings says at least 3 increasing angles but postulates a true 'trumpet curve' being best) Actually I'm planning to utilize the "Grunt Gasket" in this manner, to not only add length "header" to my exhaust tract but to get an extra 2-3 angles of increased divergence before exhaust dumps into the muffler.

#2 - that 90deg bend sucks but is worthwhile because it allows the exhaust system to have both length and a "bloom chamber" (far rear side of muffler has big expanding chamber, the gas in there passes through the 3 holes in the baffle-wall and then has to pass along the entire front side to the OEM exit) Thankfully you can greatly smooth-out that 90deg area, and increase flow nearly 20% volume-wise in doing so (the muffler-mount bolts are the 'limiting factor' when doing this, oh and being careful not to destroy that soft lead-type gasket)

I like where you're thinking, and do agree it's surely a "keep more 'in-system'" for fuel-efficacy/pollution/EPA, but I'm still scratching my head at the step and don't think your flow schema is the answer :/ I say that because, if it were, you'd want it on the top not around the entire perimeter of the port, no? I'll also admit I dislike basing things off piston wash patterns, are they truly that easy to read? My understanding was reading plugs is a long-term experience skill and still "as much art as science" kinda thing, and that piston wash-patterns were much harder than plugs to actually glean proper info from (am just worrying of getting false-positive assumptions taken as givens here!)

I cannot help picturing the gas' movement, at first I was thinking "If a lip is good, then my super-chamferred edging, which I thought helped flow, is *bad*" but not anymore... How uniform is that lip around the port? I guess now I'm starting to think it's for "exhaust pulse control". We try making 'peaks' on exhaust ceilings, chamfering/rounding the edge more in the center, etc etc to "let the exhaust gas flow more-gently/easily into the port".... But since we don't use pipes and our ports are barely an inch if even 1", I speculate the "post port-entry area" is being utilized as a header/pipe of sorts, and that having a lip around the edge of it like that would form a more "uniform" pulse, I keep picturing the gas having to go through that "tight choke" and can totally see it causing a 'controlled bloom' of the exhaust gas (and exhaust pulse "tightness" seems to be a pretty critical thing, actually in the 70's&80's racing bike manufacturers were tightening-up the divergence of their exhaust ports, yet the chainsaw world sees for example Stihl making the 088-->880 exhaust port have way more divergence, its flange is like 50% larger than the 088's, cannot help but think that Stihl "bucking the trend" is because we don't have pipes so have to make-do with the lil box systems we have....and on that note, IMO, Stihl nailed it w/ the 880 muffler design, hardly anything I'd touch except its final exit hole size, just enlarge a lil and leave it alone ;D )

Have you seen the cs590 muffler? Certainly is a "keep the gas in-system" setup, not only a 2-part (front&back portions with a perforated baffle-wall separating them) but the exit is an inches-long tube that begins in the front portion, instead of the usual "hole in the wall, with deflector".... Am not surprised that some seem to have problems when "modding" that muffler by means of putting a hole right at the top where the flange would be able to bleed pressure, have begun seeing such muffler mods as "short circuiting" or "bypassing" the muffler (which is definitely a bad idea, I mean sure the OEM exits are under-sized almost universally but in so many cases the move is to simply enlarge the OEM hole & otherwise rely on the OEM design)

Yknow as I see Stihl upping the bore on 661 from their 660 (54mm to 56mm, they reduced stroke 3mm so the displacement stayed equivalent at 91cc) and kept getting the impression that "more over-squared is better", but when looking back at my cs590 build the bore is 45 with 37mm stroke....That's the same stroke as a 661.... Since bore/stroke aren't in any megathread I can see, figure it's fair game to ask for any input / thoughts on this, in my mind it's "Why would Stihl be over-squaring even more when Echo is over-stroking?" and I know "different ways to skin a cat", of course, but just hoping to better-understand them.I agree with the above, and bore/vs/stroke make a difference also even in the same size saw.

Epoxy it'll take me a few reads before replying properly so just wanted to be clear I fully agreed & took no offense, sadly the reality is that I'm looking to dig-into something that doesn't fit EITHER (unless this thread were titled The Exhaust System which probably would be more apt IMO but maybe there's a muffler Part that I'm not remembering, will check!)

But yeah zero offense taken, IMO the muffler is a massively under-exploited area on our builds, I think most are "tossing the baby out with the bathwater" because they know OEM's are choked & that un-choking helps, they also know there's no usage of acoustics/sonic waves because calculating pipes is hard enough a box would be impossible, so they basically stop there and just "Make sure 'It can breathe'", virtually zero regard for exit sizing out of the muffler, for pressure on the flange, or for vacuum out-of the exhaust port (which can be induced by increased divergence of the walls of passage out-of the port, which is a massive part of my interest in these Grunge Gaskets -- should have mine made today & hopefully installed sometime this week, just cutting-out an exhaust flange from an extra 660 jug!)

After 1st reads of your post I will say I keep dwelling on:

"In my mind, saw size is a spectrum of displacement. A 25cc saw does not behave like a 120cc saw. Timing numbers are NOT the same. In a nutshell, the smaller displacement a saw has the more degrees it will need to create power and the less degrees it will need to fill/empty spaces."

^this idea of changing things for-displacement is just not really mentioned in Blair or Jennings' books (I mean there is some consideration but it's on the order of "10-->150cc, 150-->250cc" not 50cc-->90cc) and the 2511t to 395 comparison isn't fair because the former is a "recycling/high efficiency" modern build (just like I'd expect radically different timing#'s between a 151t and a 020t or a 660)

Just thoughts...am still in my 1st year of this kinda stuff lol.. but if displacement is making so much more difference for us than it is for "most other 2-strokes" then it stands to reason the difference would be due to our lack of pipes (which is the primary difference, followed by gearing/transmissions, so far as I can tell...my understanding is those are the reasons that, say, a motorbike's exhaust will be like 200deg duration or other way-higher-than-saws, I know some is due to reeds but even reed intake saws don't have #'s anywhere near motorbikes..)