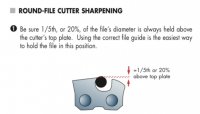

I measured that cutter up as well as I could and came up with a 30 deg top plate angle, 0 deg tilt, and my file (in the Granberg) is 26% above the top plate.

The 26% kind of surprised me.

The chain is a Laser chain (Carlton)

Variables would be that the tooth lengths on this chain are all over the place and are getting filed back a fair way from new. That would mean the profiles on the cutters are a little different along the chain.

Depth gauges are set at 0.025" using a progressive filing gauge.

I certainly find that the further back the cutter is filed, the faster the chain cuts.

The chain looks a bit of a joke but it rips!

View attachment 317315

pics of one of the cutters.

View attachment 317314