- Local time

- 2:58 AM

- User ID

- 6263

- Joined

- May 27, 2018

- Messages

- 1,255

- Reaction score

- 7,572

- Location

- Omaha, NE.

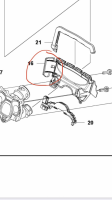

I wonder if your tank vent was giving you issues. When you removed the fuel cap the vacuum surge caused the bubbles.

I've seen lots of fuel boiling in a alloy crankcase fuel tank but never in a poly thermal isolated tank.

That could be very true. I didn't try super hard to restart it as the heat was getting to me and I had to drag the wood uphill to the truck. If I would have asked the homeowner instead of relying on the pictures, my bad, I would have skipped the score but it is nice hard maple. Nice having multiple saws to work with and soon will have a 550xpg in the lineup.