5shot

Well-Known OPE Member

- Local time

- 5:50 AM

- User ID

- 16899

- Joined

- Jun 26, 2021

- Messages

- 4

- Reaction score

- 25

- Location

- Colbert, WA

I bought this saw back in 2007 for firewood cutting, but a couple years later we moved cities and away went our wood stove. It has not seen much use at all, and I finally decided I should mod the muffler and get it out on my dad's property to put it to use.

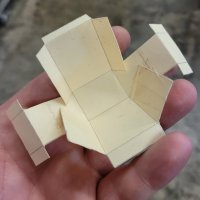

I liked the Lakeside mod, but don't have any welding equipment, so I ended up getting the Husky Diverter and spark screen. I did a quick calculation on the area of the holes in the baffle, and like Lake had said before, they aren't the problem, the tiny exit hole is. I used an awl to transfer the entire area of the diverter opening onto the side of the muffler and then drilled and dremeled the port out. It ran good, but the screen choked off half the air flow. We have fires all over the place, so running without a screen is a no go. I decided I need more screen area to achieve what he had done, so I set about making a pattern for a screen that had enough flow. This one ends up with at least 3x the flow of the flat screen and probably closer to 4. That gives more than 150% of the flow required to utilize the entire port area (which is the same size as the muffler gasket opening. I would guess it is much larger than the area of the exhaust port at the cylinder. I ordered some 30Mesh from Amazon and it worked damn good for the first try. It is a tad tight, since the thickness of the screen is a bit more than the manila folder, but it doesn't really need to come back out. You can burn off the junk by removing the diverter only. Saw idles great and runs really well. I tuned it back to just under 14K at WOT, but I'll burry it in some wood and retune to see what it can do.

I liked the Lakeside mod, but don't have any welding equipment, so I ended up getting the Husky Diverter and spark screen. I did a quick calculation on the area of the holes in the baffle, and like Lake had said before, they aren't the problem, the tiny exit hole is. I used an awl to transfer the entire area of the diverter opening onto the side of the muffler and then drilled and dremeled the port out. It ran good, but the screen choked off half the air flow. We have fires all over the place, so running without a screen is a no go. I decided I need more screen area to achieve what he had done, so I set about making a pattern for a screen that had enough flow. This one ends up with at least 3x the flow of the flat screen and probably closer to 4. That gives more than 150% of the flow required to utilize the entire port area (which is the same size as the muffler gasket opening. I would guess it is much larger than the area of the exhaust port at the cylinder. I ordered some 30Mesh from Amazon and it worked damn good for the first try. It is a tad tight, since the thickness of the screen is a bit more than the manila folder, but it doesn't really need to come back out. You can burn off the junk by removing the diverter only. Saw idles great and runs really well. I tuned it back to just under 14K at WOT, but I'll burry it in some wood and retune to see what it can do.

Attachments

Last edited: