Lightning Performance

Here For The Long Haul!

- Local time

- 11:32 PM

- User ID

- 677

- Joined

- Jan 26, 2016

- Messages

- 10,991

- Reaction score

- 28,059

- Location

- East of Philly

Leave it alone is your best bet.The heat/wear factor is my concern... Doing in-tree work is few and far between for me and this saw is more of a toy for me than anything else. I usually do dead wooding and pruning with a silky sugoi but I fancy being lazy for a bit. I don't do big work. Buying this saw was more of a lockdown project for me whilst I haven't got much on!

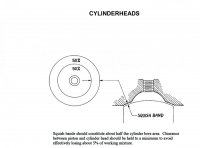

Check the piston clearance for 0.014 or more. The rest was covered. Don't mess with the upper transfers.