wcorey

Pinnacle OPE Member

- Local time

- 3:46 AM

- User ID

- 29

- Joined

- Dec 11, 2015

- Messages

- 1,078

- Reaction score

- 4,662

- Location

- ma usa

Since Niko (and company) effed the other thread up I figured I’d start a fresh one…

Finally picked up my very first 066 a few months back, I’m pretty cheap and pretty patient with acquiring saws and this is one model where a good deal has successfully eluded me for years.

It was a red light saw-in-a-box deal that was too good to pass up, missing a lot of parts but the big essentials were mostly there and in good shape. Needed a piston, top handle, brake handle, air cleaner cover and a bunch of small stuff, a lot of which I can live with aftermarket parts on.

Unfortunately turned out the cylinder’s an 064, didn’t notice at the time ‘cause they look sorta similar to the old 066 ones. Not that it would have changed anything… So good timing on these cylinders.

Slowly accumulating parts for it and patiently waited for the mmws/hl cylinders to get done.

Air cleaner cover is the last major piece I haven’t found but a least not essential to running it.

Was going to hold off buying the mmws/hl cyl until I heard some feedback on how they came out but the deal o’ the day thing was too good to pass up so I grabbed a couple.

Still waiting on a few small parts before I can run it.

Overall the cylinders look pretty good and so far I’m happy enough with what I got.

Numbers look good, more or less ‘as advertised’, 102 ex, 20 bd, 81 int without base gasket.

Squish about .019” without gasket (one issue here though, see below). Casting quality mostly looks good, particularly inside the transfers where it often lacks. Good thick base, piston looks decent with no obvious issues. Caber rings, a nice addition.

The Bad… well there is some… I wouldn’t drop in/run either of them without a careful once over, I’d consider it absolutely essential.

Nothing that can’t be addressed with some light grinding/cleanup though.

Really better than/nothing more than what I’ve come to expect with the chicom stuff in general.

Lots of casting flash and plating ‘crusties’. Beveling is inconsistent and sketchy, one was generally better than the other. Ex port roof is kinda flat.

One cylinder had a sort of pocket in the bottom corner of a lower transfer with some nasty looking flash and ragged edges of plated aluminum waiting to fall off. And in behind there was a substantial amount of what appeared to be gritty blasting media all stuck up in there. Didn’t wash/blow out, needed to be scrapped out.

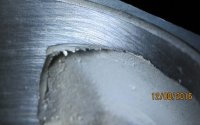

Both had a lot of crusty plating along the edge of the exhaust port openings, one on the roof, the other the floor. I mean relatively big chunks that could be broken off without much effort, had a small pile just from poking around with a screw driver. Miscellaneous smaller spots randomly scattered on other ports.

And that pic is after I chipped the big stuff off already...

The plating chips easily on the corners.

A big piece of sparkplug thread was barely hanging on, waiting to break off on the end of one hole.

Guess I need to start another page for more pics...

Finally picked up my very first 066 a few months back, I’m pretty cheap and pretty patient with acquiring saws and this is one model where a good deal has successfully eluded me for years.

It was a red light saw-in-a-box deal that was too good to pass up, missing a lot of parts but the big essentials were mostly there and in good shape. Needed a piston, top handle, brake handle, air cleaner cover and a bunch of small stuff, a lot of which I can live with aftermarket parts on.

Unfortunately turned out the cylinder’s an 064, didn’t notice at the time ‘cause they look sorta similar to the old 066 ones. Not that it would have changed anything… So good timing on these cylinders.

Slowly accumulating parts for it and patiently waited for the mmws/hl cylinders to get done.

Air cleaner cover is the last major piece I haven’t found but a least not essential to running it.

Was going to hold off buying the mmws/hl cyl until I heard some feedback on how they came out but the deal o’ the day thing was too good to pass up so I grabbed a couple.

Still waiting on a few small parts before I can run it.

Overall the cylinders look pretty good and so far I’m happy enough with what I got.

Numbers look good, more or less ‘as advertised’, 102 ex, 20 bd, 81 int without base gasket.

Squish about .019” without gasket (one issue here though, see below). Casting quality mostly looks good, particularly inside the transfers where it often lacks. Good thick base, piston looks decent with no obvious issues. Caber rings, a nice addition.

The Bad… well there is some… I wouldn’t drop in/run either of them without a careful once over, I’d consider it absolutely essential.

Nothing that can’t be addressed with some light grinding/cleanup though.

Really better than/nothing more than what I’ve come to expect with the chicom stuff in general.

Lots of casting flash and plating ‘crusties’. Beveling is inconsistent and sketchy, one was generally better than the other. Ex port roof is kinda flat.

One cylinder had a sort of pocket in the bottom corner of a lower transfer with some nasty looking flash and ragged edges of plated aluminum waiting to fall off. And in behind there was a substantial amount of what appeared to be gritty blasting media all stuck up in there. Didn’t wash/blow out, needed to be scrapped out.

Both had a lot of crusty plating along the edge of the exhaust port openings, one on the roof, the other the floor. I mean relatively big chunks that could be broken off without much effort, had a small pile just from poking around with a screw driver. Miscellaneous smaller spots randomly scattered on other ports.

And that pic is after I chipped the big stuff off already...

The plating chips easily on the corners.

A big piece of sparkplug thread was barely hanging on, waiting to break off on the end of one hole.

Guess I need to start another page for more pics...