You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hybrid clonesaw 365 with a 390 topend - aka the "86'r from youtube"

- Thread starter upstateamish

- Start date

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Me too! If it works, the next prototype will need some additonal case trenching on the clutch side to case match the transfers.

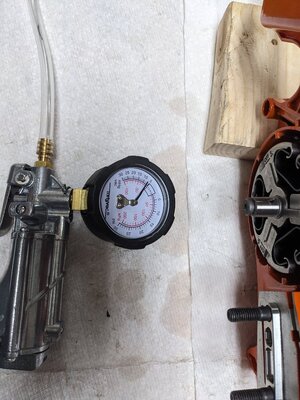

And when I pressure vac tested last night and had a small leak around the crank bushing, so I've pulled the seal and bushing out and did a small amount of 1184 around the base (as I don't have the overpriced o-ring)

more to come as more parts arrive.

And when I pressure vac tested last night and had a small leak around the crank bushing, so I've pulled the seal and bushing out and did a small amount of 1184 around the base (as I don't have the overpriced o-ring)

more to come as more parts arrive.

Ketchup

Epoxy member

- Local time

- 1:01 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,477

- Location

- Colorado

Looking at 385/390, there’s no bushing. The oil gear just rides on the pump. Seems like that would overheat the gear, but it would eliminate the bushing/o-ring/seal problem. Could you do that with a tighter ID seal?

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Yeah, I don't have an actual 385/390 to reference but from what I can tell in my research they changed their bearing style to move to an integrated seal (like the 562 series saws.)

Here's one I found:

Which looks like it was originally seperate (seal/bearing)

But I *think* it changed from using something like this seperate type of seal that pressed in ?

www.boerger-motorgeraete.de

www.boerger-motorgeraete.de

Either way, to use the bearing for the 390, the case would need to be bored out to fit. We'll see how well I can get this to seal, I think it's close.

Maybe the integrated seal bearing approach is a task for the 4th prototype

Here's one I found:

Which looks like it was originally seperate (seal/bearing)

But I *think* it changed from using something like this seperate type of seal that pressed in ?

Husqvarna Kettensäge | Motorsäge Radialdichtung

original Husqvarna Ersatzteil / Zubehör Artikelbeschreibung SEALING RADIAL Ersatz für Artikel Nr.: 503 26 02‑10, 503 18 45‑01 Passend für: Motorsägen,…

www.boerger-motorgeraete.de

www.boerger-motorgeraete.de

Either way, to use the bearing for the 390, the case would need to be bored out to fit. We'll see how well I can get this to seal, I think it's close.

Maybe the integrated seal bearing approach is a task for the 4th prototype

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Alright. after searching through the bins for a bunch of random parts along the way... Got it together. I have a couple parts that still need to be ordered.

But first fire is a success!

Long form vid (skip to 45 seconds if you don't want to see me yarding away on it...)

- I didn't hear it when I was running it but I hear some knocking in the vid that I *think* (hope) is the air duct/deflector hitting... the flywheel... it was aftermarket didn't seem to sit flush and I was not sure how it would go.

- Carb is not tuned & the throttle cable was sticking open slightly. I've remediedt that but ran out of daylight.

Near the end of the vid I was getting some weird spitback firing issues that I assumed was carb related so after it it died a couple times I stopped so I could pull the muffler to see how the piston looked, check bolts (and now that I've listened to the vid, try and find the source of that knock)

Still seems to pull over ok and piston looks good with no scoring (yet)

But first fire is a success!

Long form vid (skip to 45 seconds if you don't want to see me yarding away on it...)

- I didn't hear it when I was running it but I hear some knocking in the vid that I *think* (hope) is the air duct/deflector hitting... the flywheel... it was aftermarket didn't seem to sit flush and I was not sure how it would go.

- Carb is not tuned & the throttle cable was sticking open slightly. I've remediedt that but ran out of daylight.

Near the end of the vid I was getting some weird spitback firing issues that I assumed was carb related so after it it died a couple times I stopped so I could pull the muffler to see how the piston looked, check bolts (and now that I've listened to the vid, try and find the source of that knock)

Still seems to pull over ok and piston looks good with no scoring (yet)

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

ok, I believe I found the source of that knock. I sheared the timing key on the flywheel when the lock washer came loose.

I happen to have a spare (as I'll be doing prototype 4) so I swapped the good one on. I figure this one can be used later for adjusting timing if I need to.

Also added the deflector on the muffler to open it up like the others I have.

With those in place (and throttle linkage freed up) it seems to be running decent. I know it still needs a little carb tweaking (to stop it from dying out at idle) but it's raining so this is all I'll plan to do at the moment.

I'm pretty excited to have things to this point

I happen to have a spare (as I'll be doing prototype 4) so I swapped the good one on. I figure this one can be used later for adjusting timing if I need to.

Also added the deflector on the muffler to open it up like the others I have.

With those in place (and throttle linkage freed up) it seems to be running decent. I know it still needs a little carb tweaking (to stop it from dying out at idle) but it's raining so this is all I'll plan to do at the moment.

I'm pretty excited to have things to this point

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Assuming things look good once I pull the muffler and check things over one last time I should be able to get some heat cycles in over the next week.

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Jake Dykstra

Super OPE Member

- Local time

- 12:01 AM

- User ID

- 7947

- Joined

- Nov 25, 2018

- Messages

- 261

- Reaction score

- 740

- Location

- NW Washington

I did a 372 at 28 degrees of blow down. It sounded great but struggled in the cut.

With case volume similar to 390 or less I would bet it would be much happier at 20 degrees bd. But I wouldn't go higher than 129 degrees on the transfers with an 82 intake.

I'd bet 96.5/118/78 would be the sweet spot

With case volume similar to 390 or less I would bet it would be much happier at 20 degrees bd. But I wouldn't go higher than 129 degrees on the transfers with an 82 intake.

I'd bet 96.5/118/78 would be the sweet spot

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

Got a chance to get a bar and chain on it and a couple test cuts in some ash. Did a video of side by side cuts with my 500i.

The saw I ran was the 500i, but looking at how close the numbers for cuts 2 and 3 are, I am chalking up 500i's 1st timed cut to not using as much pressure as the second/third. The prototype seems to be running strong & idling well after the cuts

The saw I ran was the 500i, but looking at how close the numbers for cuts 2 and 3 are, I am chalking up 500i's 1st timed cut to not using as much pressure as the second/third. The prototype seems to be running strong & idling well after the cuts

upstateamish

Super OPE Member

- Local time

- 3:01 AM

- User ID

- 17558

- Joined

- Jul 13, 2021

- Messages

- 120

- Reaction score

- 432

- Location

- upstate new york

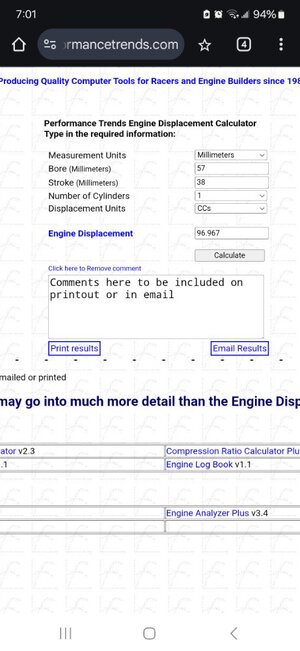

Current Prototype #3 specs: for those who wish to recreate what I've got here

Case - 365/372 variety with material removed to fit the diameter and width of the crank

Chain - 24" bar with dukes hard chrome 3/8 .050 full chisel skip tooth

Cylinder -57mm 390 big bore from wolf creek (non-Titanikel)

Crank - 390 crank (sides machined down to fit in the case width wise)

Bearings - SKF 6003 C3 Deep Groove Ball Bearing (with 25 x 35 x 1mm spacers to take up

Crankshaft Bushing Sleeve - (pto side) custom machined sleeve to fit crank and stock seal (no o-ring, but slight amount of threebond 1184 as a seal for it on the shaft)

Flywheel Seal - 17 x 26 x 7

Carb - 395 carb (with 372 choke* lever attachement)

X-torq: top cover, air filter horn & choke lever

Muffler - Opened up with an Echo exhaust deflector

This week is gonna be all rain here and I'm working on doing some garage re-configuration but if I get some time i'll see what I can come up with. I think I may have a 28" bar in sthil/husky side and a longer husky (36"... I will have to check?) one I have for an alaskan sawmill.

Case - 365/372 variety with material removed to fit the diameter and width of the crank

Chain - 24" bar with dukes hard chrome 3/8 .050 full chisel skip tooth

Cylinder -57mm 390 big bore from wolf creek (non-Titanikel)

Crank - 390 crank (sides machined down to fit in the case width wise)

Bearings - SKF 6003 C3 Deep Groove Ball Bearing (with 25 x 35 x 1mm spacers to take up

Crankshaft Bushing Sleeve - (pto side) custom machined sleeve to fit crank and stock seal (no o-ring, but slight amount of threebond 1184 as a seal for it on the shaft)

Flywheel Seal - 17 x 26 x 7

Carb - 395 carb (with 372 choke* lever attachement)

X-torq: top cover, air filter horn & choke lever

Muffler - Opened up with an Echo exhaust deflector

Yup, see above. agreed, I'll have to find some bigger wood to test it out in.So this is the 390 crank and top end? If so 88cc vs 80cc. More biggly wood please.

Yup, this is a 57mm top end.I think it’s a 57mm top end, so 94cc vs 80cc. Definitely needs a long bar comparison.

This week is gonna be all rain here and I'm working on doing some garage re-configuration but if I get some time i'll see what I can come up with. I think I may have a 28" bar in sthil/husky side and a longer husky (36"... I will have to check?) one I have for an alaskan sawmill.

Last edited:

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 3:01 AM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,796

- Location

- South Carolina

Ketchup

Epoxy member

- Local time

- 1:01 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,477

- Location

- Colorado

Current Prototype #3 specs: for those who wish to recreate what I've got here

Case - 365/372 variety with material removed to fit the diameter and width of the crank

Chain - 24" bar with dukes hard chrome 3/8 .050 full chisel skip tooth

Cylinder -57mm 390 big bore from wolf creek (non-Titanikel)

Crank - 390 crank (sides machined down to fit in the case width wise)

Bearings - SKF 6003 C3 Deep Groove Ball Bearing (with 25 x 35 x 1mm spacers to take up

Crankshaft Bushing Sleeve - (pto side) custom machined sleeve to fit crank and stock seal (no o-ring, but slight amount of threebond 1184 as a seal for it on the shaft)

Flywheel Seal - 17 x 26 x 7

Carb - 395 carb (with 372 choke* lever attachement)

X-torq: top cover, air filter horn & choke lever

Muffler - Opened up with an Echo exhaust deflector

Yup, see above. agreed, I'll have to find some bigger wood to test it out in.

Yup, this is a 57mm top end.

This week is gonna be all rain here and I'm working on doing some garage re-configuration but if I get some time i'll see what I can come up with. I think I may have a 28" bar in sthil/husky side and a longer husky (36"... I will have to check?) one I have for an alaskan sawmill.

I think the 36” will make you smile.

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 3:01 AM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,796

- Location

- South Carolina

Think a Dremel could fix that?No space on the case for bottom fed transfers.

Ketchup

Epoxy member

- Local time

- 1:01 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,477

- Location

- Colorado

Think a Dremel could fix that?

Afraid not. 390 is just about the widest chainsaw cylinder in existence. The transfer lowers would stick out past the deck on the FW side and the chain brake area would have to be hacked to pieces.

Similar threads

- Replies

- 4

- Views

- 756