Ok, weekend update - parts have shown up

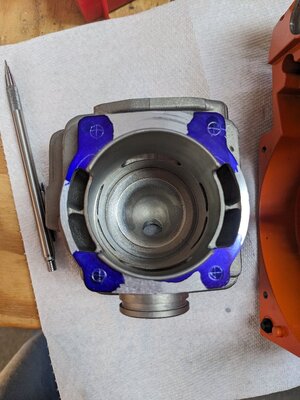

Round 2 of the cylinder in process: one of my plugs came out when drilling (upper left on this picture, should't matter though, everything still tightens up.)

I decided to replace the 056 piston due to current fitment & there are a couple vertical scratches that would impact compression.

Since I have a few of 390 pistons accumulating here, I decided to to try turning one to a single ring. My thought was taking the top ring portion out would allow it to spin all the way around in the cylinder. As you can see on my first attempt I found out where the top is thin (as others noted) however, it did spin all the way around in the cylinder.

So, in the interest of learning, science (and not haven't another 56mm piston to turn down with this wrist pin diameter) I gave it another shot.

I turned the second one with a slight dome to it starting around where the ring pin ended (hopefully it's thick enough here to not blow out) we'll see.

Weight after all the machine work/ lightening - 108 grams with a ring, the wrist pin & clips (which ended up being the same weight as the 056 piston setup)

got things tightened down the block (no base gasket, but with 1184 so have to wait for it to setup) & I'll do a leakdown test tomorrow

The numbers (without a base gasket): which from the threads I've been digging through on 390 porting sound like it may work ok as a base to work from.

- Squish: 0.025 (I was limited with where things ended up by taking off the 1st the ring)

- Exhaust: 96

- Transfers: 120

- Intake: 79

If this works, this approach might be better. (less machine work to get things to fit & you're able to use a standard 55mm ring.) I think without the 395 connecting rod on the 390 crank, you probably could just use the regular piston as the connecting rod is about 7mm shorter.

Assuming the leakdown test passes, I hope to put everything back together and test fire it. fingers crossed