- Local time

- 7:25 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,643

- Reaction score

- 63,590

- Location

- Strong Island NY

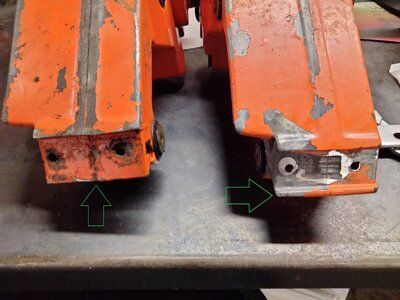

Jeez, that’s a headache. Annoying to weld as well as it’s near and edge and will be hard to get perfectly clean.

They often cast in thicker metal where screw holes will go. You’re getting really close to the edge there, I’d be careful not to tighten your insert up and crack the tank. A good application for Loctite.

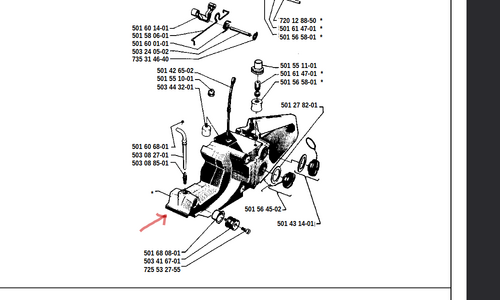

The fact that it goes into the oil tank shouldn’t matter much. Many Husky’s have screws that enter the tank.

They often cast in thicker metal where screw holes will go. You’re getting really close to the edge there, I’d be careful not to tighten your insert up and crack the tank. A good application for Loctite.

The fact that it goes into the oil tank shouldn’t matter much. Many Husky’s have screws that enter the tank.