You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to square file

- Thread starter skippy

- Start date

Leafy

Super OPE Member

I'll have to keep looking. I hate buying tools marketed for something specific when there is usually an industrial version that lasts twice as long for half the price. So the angle between the two cutting surfaces should have a minimal radius is what you mean when you say square right? Because the double bevel, triangle, and 6 side don't have 90deg corners between the side of the file that cuts the top plate and the side plate.

I'll have to wait till I either get a non cracked 372 crank case from huztl or a splined clutch drum for the China saw to do a 3/8th chain

I'll have to wait till I either get a non cracked 372 crank case from huztl or a splined clutch drum for the China saw to do a 3/8th chain

- Local time

- 4:08 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,529

- Reaction score

- 150,463

- Location

- East Jordan, MI

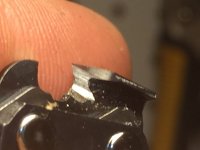

You must've just done the dishes....This was a 3/8 round file conversion chain. I am doing better, but still a long way to go. Chain was basically rocked by previous owner.

Here is how it cut.

mdavlee

Hillbilly grinder

- Local time

- 4:08 AM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,634

- Location

- TN

I'll have to keep looking. I hate buying tools marketed for something specific when there is usually an industrial version that lasts twice as long for half the price. So the angle between the two cutting surfaces should have a minimal radius is what you mean when you say square right? Because the double bevel, triangle, and 6 side don't have 90deg corners between the side of the file that cuts the top plate and the side plate.

I'll have to wait till I either get a non cracked 372 crank case from huztl or a splined clutch drum for the China saw to do a 3/8th chain

It’s not 90 degrees but it needs to have sides <=>

brshephard

Stihl saws, Husky women

I'll have to keep looking. I hate buying tools marketed for something specific when there is usually an industrial version that lasts twice as long for half the price. So the angle between the two cutting surfaces should have a minimal radius is what you mean when you say square right? Because the double bevel, triangle, and 6 side don't have 90deg corners between the side of the file that cuts the top plate and the side plate.

I'll have to wait till I either get a non cracked 372 crank case from huztl or a splined clutch drum for the China saw to do a 3/8th chain

The angle where the file faces meet should be greater than 90, maybe 120 or so

A triangle file is 60 so you won't be able to file the top and side at the same time.

Maybe you could butt two triangle files together face to face. That would give you a 120 degree angle.

Or just buy a grinder

- Local time

- 4:08 AM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

There is no radius to a square cornerI'll have to keep looking. I hate buying tools marketed for something specific when there is usually an industrial version that lasts twice as long for half the price. So the angle between the two cutting surfaces should have a minimal radius is what you mean when you say square right? Because the double bevel, triangle, and 6 side don't have 90deg corners between the side of the file that cuts the top plate and the side plate.

I'll have to wait till I either get a non cracked 372 crank case from huztl or a splined clutch drum for the China saw to do a 3/8th chain

Leafy

Super OPE Member

It’s not 90 degrees but it needs to have sides <=>

So no safe edges, blunt not tapered (or at least never use the tapered section to file with), and minimal radius. Cause there's got to be a radius on the outside edge of a cutting tool or there will be as soon as you take a cut with it.

- Local time

- 3:08 AM

- User ID

- 394

- Joined

- Jan 3, 2016

- Messages

- 5,313

- Reaction score

- 24,010

- Location

- West of Kansas City

Has this thread been infested?

- Local time

- 4:08 AM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

Full chisel has an outside square cornerSo no safe edges, blunt not tapered (or at least never use the tapered section to file with), and minimal radius. Cause there's got to be a radius on the outside edge of a cutting tool or there will be as soon as you take a cut with it.

- Local time

- 4:08 AM

- User ID

- 1222

- Joined

- Apr 30, 2016

- Messages

- 2,550

- Reaction score

- 15,306

- Location

- Central CT

- Local time

- 1:08 AM

- User ID

- 2003

- Joined

- Oct 18, 2016

- Messages

- 29,506

- Reaction score

- 132,028

- Location

- GFY

I like that forward lean. It should feed real good.3/8” LP. Stihl 63PS. Just a fuzz low.

View attachment 127704 View attachment 127705 View attachment 127706 View attachment 127707

- Local time

- 4:08 AM

- User ID

- 1222

- Joined

- Apr 30, 2016

- Messages

- 2,550

- Reaction score

- 15,306

- Location

- Central CT

What kind of chain is that? I’ve been using Carlton K1L for .325.View attachment 127700

.325 isn’t that tough. I use a double bevel

Redfin

Meh...

- Local time

- 4:08 AM

- User ID

- 159

- Joined

- Dec 24, 2015

- Messages

- 7,653

- Reaction score

- 40,039

- Location

- Central Pa

Looks like you need to do some dishes.There is no radius to a square corner

View attachment 127689 View attachment 127690 View attachment 127691 View attachment 127692 View attachment 127693

- Local time

- 4:08 AM

- User ID

- 1222

- Joined

- Apr 30, 2016

- Messages

- 2,550

- Reaction score

- 15,306

- Location

- Central CT

Thanks. Hopefully my little 40cc saws will have the stones to pull it. Lol.I like that forward lean. It should feed real good.

- Local time

- 1:08 AM

- User ID

- 2003

- Joined

- Oct 18, 2016

- Messages

- 29,506

- Reaction score

- 132,028

- Location

- GFY

Lol hopefully the rakers are tall.Thanks. Hopefully my little 40cc saws will have the stones to pull it. Lol.

- Local time

- 4:08 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,529

- Reaction score

- 150,463

- Location

- East Jordan, MI

At least one. Like a cereal bowl er sumfinLooks like you need to do some dishes.

Similar threads

- Replies

- 0

- Views

- 215