STOVE

Well-Known OPE Member

- Local time

- 9:11 AM

- User ID

- 34149

- Joined

- Aug 29, 2025

- Messages

- 174

- Reaction score

- 467

- Location

- Eastern NC

I am getting ready to start a 290-390 conversion.

The Dukes cylinder that showed up has a few things that need to be addressed. However for the price i am very satisfied. Below are a few of the items that i was hoping to massage.

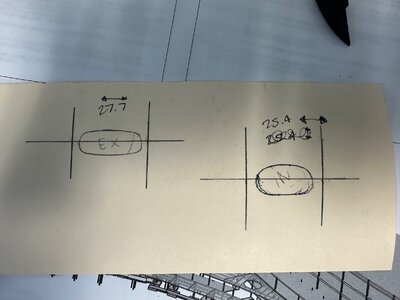

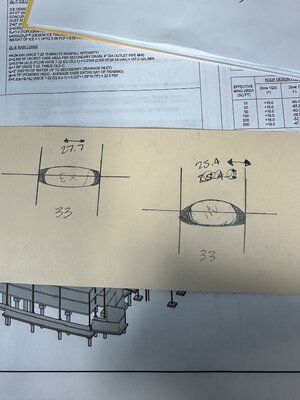

There is a slight lip all the way around the intake port. Can I use files and gradual grit sandpapers to clean this up?

The exhaust port needs a polish and edges cleaned up. Will polish this with a dremel. I don’t know if the shape is optimal however I will take off any lip or rough edge with some file and sandpaper work

The transfers have very sharp and somewhat uneven edges on one side. Will likely use small finger length files to round off these sharp edges.

Am I being too ambitious here in thinking I can use metal files? I am worried with it being my first time I will take away too much material attempting to use the dremel. Any help would be appreciated. I do have a Poulan 40cc jug I planned on practicing on with the files first.

The Dukes cylinder that showed up has a few things that need to be addressed. However for the price i am very satisfied. Below are a few of the items that i was hoping to massage.

There is a slight lip all the way around the intake port. Can I use files and gradual grit sandpapers to clean this up?

The exhaust port needs a polish and edges cleaned up. Will polish this with a dremel. I don’t know if the shape is optimal however I will take off any lip or rough edge with some file and sandpaper work

The transfers have very sharp and somewhat uneven edges on one side. Will likely use small finger length files to round off these sharp edges.

Am I being too ambitious here in thinking I can use metal files? I am worried with it being my first time I will take away too much material attempting to use the dremel. Any help would be appreciated. I do have a Poulan 40cc jug I planned on practicing on with the files first.