You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

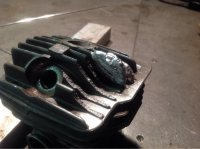

Fin damage... To run or not to run...

- Thread starter bplust

- Start date

- Local time

- 6:12 PM

- User ID

- 309

- Joined

- Dec 29, 2015

- Messages

- 7,954

- Reaction score

- 50,433

- Location

- Ontario, Canada

I'd probably run it. Maybe run it a little fat on the tune or try a higher octane fuel to help keep it a few degrees cooler. Opening up the muffler a bit will also help get rid of unnecessary heat.

Gary Courtney

Pinnacle OPE Member

- Local time

- 5:12 PM

- User ID

- 413

- Joined

- Jan 5, 2016

- Messages

- 1,002

- Reaction score

- 2,473

- Location

- Froglevel

Run it till she quits!

- Local time

- 6:12 PM

- User ID

- 377

- Joined

- Jan 1, 2016

- Messages

- 19,403

- Reaction score

- 111,343

- Location

- Warren Center, PA

I've ran a 385 for ten years that's in worse shape than that. Still blows 150psi. I cut 15-20 cords a year. If I was making a living with it I'd swap it out. For a firewood saw run it.

- Local time

- 6:12 PM

- User ID

- 309

- Joined

- Dec 29, 2015

- Messages

- 7,954

- Reaction score

- 50,433

- Location

- Ontario, Canada

- Local time

- 6:12 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,103

- Reaction score

- 147,574

- Location

- East Jordan, MI

I think it was drf255 that welded them back on

SixGun

Super OPE Member

- Local time

- 6:12 PM

- User ID

- 440

- Joined

- Jan 8, 2016

- Messages

- 280

- Reaction score

- 482

- Location

- Hackettstown NJ

I've had tig welding done on a cylinder intake and it turned out beautiful. Never did fins yet but seems doable

- Local time

- 6:12 PM

- User ID

- 309

- Joined

- Dec 29, 2015

- Messages

- 7,954

- Reaction score

- 50,433

- Location

- Ontario, Canada

- Local time

- 6:12 PM

- User ID

- 377

- Joined

- Jan 1, 2016

- Messages

- 19,403

- Reaction score

- 111,343

- Location

- Warren Center, PA

I saw one that someone did over on AS that looked real nice. Actually got me thinking when I do overhaul the 385 I may take the old cylinder to work and try welding it up.

- Local time

- 6:12 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,598

- Reaction score

- 63,202

- Location

- Strong Island NY

Ive done fin repairs.

redtractor

Super OPE Member

- Local time

- 6:12 PM

- User ID

- 553

- Joined

- Jan 16, 2016

- Messages

- 375

- Reaction score

- 1,168

- Location

- Maryland

I'd be curious about heat transfer through JB. It doesn't strike me as being a good conductor.Anyone one ever try to jb weld fins back on?Or form your own fins?

- Local time

- 6:12 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,598

- Reaction score

- 63,202

- Location

- Strong Island NY

- Local time

- 6:12 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,598

- Reaction score

- 63,202

- Location

- Strong Island NY

angelo c

Coal Member

- Local time

- 6:12 PM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,557

- Location

- Peoples Republic of North Jersey

Pssst. Don't forget to tell 'em yer shop rate is $15 per hour...and it took 40 hours to repair that awesome manly man jug some fool sent ya.

jockeydeuce

Pinnacle OPE Member

- Local time

- 3:12 PM

- User ID

- 476

- Joined

- Jan 10, 2016

- Messages

- 574

- Reaction score

- 1,591

- Location

- BC, Canada

That cylinder will probably be fine forever....I have had saws on my bench that customers have been running for extended periods with the fins so plugged with pitch and gunk that the cylinder was pretty much a solid slug (Logging saws). Not only was there no air flow, but the cylinder was insulated! .....If kept clean, there's no way a cylinder like that won't last.

.....If kept clean, there's no way a cylinder like that won't last.

Black Dog Chainsaw

Mak-Crazy

- Local time

- 6:12 PM

- User ID

- 445

- Joined

- Jan 8, 2016

- Messages

- 1,059

- Reaction score

- 3,121

- Location

- Indianola, IA

X2 on the welding. A cheaper option might be to use some aluminum brazing rod. It just needs enough contact to transfer heat. Pretty doesn't matter at this point, and it's not like they need to be real solid b/c they aren't structural.

Mark71gtx

Pinnacle OPE Member

- Local time

- 6:12 PM

- User ID

- 539

- Joined

- Jan 14, 2016

- Messages

- 1,207

- Reaction score

- 2,094

- Location

- Fuquay Varina, NC

What filler metal and Welding process do you use when repairing cylinders? The welds look clean, so I am assuming high frequency TIG? I normally weld stainless or carbon. The aluminum filler material is not something I am familiar with. Thanks!