Oh btw here's the OEM 266 guide I'd used

https://www.echo-usa.com/getattachment/bb028282-a8f4-4a42-8c21-7d5ff6dd939f/PPT-266Hes_14_102314

There's 3 guides, depending on serial# (that^ is for any serial #'s starting w/ E205, there are 2 more guides available from the page 'above' that one on Echo's site, google would get you there easy

)

More I look at this "hot spot" the more I am thinking

"you are literally feeling an engine-overlay plating, or engine//shaft interfacing overlay, this is basically mid-way between ambient-temp and *exhaust* temp", though guess I would've figured for some plastic-overlay casing if that were the deal (although I guess that part of the unit is

behind your hands/hips when in-use, so as long as it's not burning-to-the-touch (like a muff) then I imagine maybe it IS normal/OK for it to just be a super-hot area... would really love people's thoughts though, can't take it on a >3min

real use at a time because of fear that, if it's friction heat from missing heavy-grease, that I may fry something I *coulda* lubed if I'd just opened it up 1st..

~~

Also still can't find carb-adjustment screws, so while I am gonna open the muff to at least remove *some* choking, I'm holding-off from full muff-modding and air-box-opening until I can fatten carb, would very much appreciate H&L locations(or carb-model so I can find it

)

~~

On another note, while I'll leave-aside my larger/meta gripe that most of this equipment is engineered with FAR less air-flow-potential than it could/should be made with, for this specific model(ppt-266) there's the usual restricted air-box (this one does have a couple slits for air-induction, not a sealed-box like oh-so-many sub-30cc powerheads that're forced to pull air from-suction in their lil 'plastic coffins'!) but more curiously I found what appears to be a "heat-retention shield", a big metal plate that sits above the engine / under the casing's upper-plastics, I can understand them not wanting to fry the plastic up-top but this is hardly "an elegant solution" if it's what it looks like to me IE a literal "heat shield" that'll force upward heat to have to migrate-out

sideways instead of upward as it'd like....here's a pic of the part close-up style, then the actual chart I screen-shot the close-up from, so you know what I mean...my instinct is to remove mine entirely and drill vent-holes on the upper plastic casing, maybe paint its inside with red Perma so it's less-likely to warp/burn-up at all, but wanna understand it I mean it can't truly just be their engineers' attempt at "proper heat-removal from powerhead"

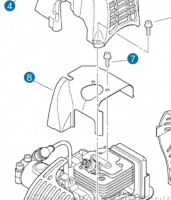

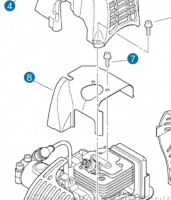

Close-up of piece I mean (#8 here:

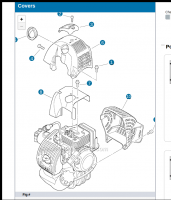

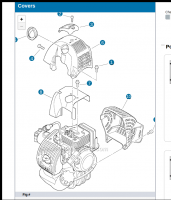

aaand the larger view of same pic, to show where #8 is...seems its purpose is strictly to prevent frying the upper plastic casing, at the expense of obnoxiously-impaired air-cooling of the powerhead :/

Would love people's thoughts on this, am going to start a more 'meta' thread on this because it's been pissing me off, some of my top-handles' air-boxes are literally sealed-coffins I mean the only air-inlet to the carb/air-filter "coffin" is that casing-gap at the H&L screw-port, I make "Frog Skinz" type air-filtered holes on all my saw's intakes which, along w/ muff modding, is usually essential IMO (wish I could find a good&'final-word' answer on

"Does *any* front- or back-pressure benefit these types of 2-strokes, or would the block's optimal condition be one with NOTHING on the air-inlet or exhaust-outlet ports, just wide-open to the air so it can draw&expel air w/o any restrictions whatsoever?", think I'll try for an answer on StckExchange again if nobody here knows, am quite sure it is the case but want verification ;D