You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Echo 490 to ported 4910…to cs-5484

- Thread starter Ketchup

- Start date

038, but I would probably keep 50mm bore for an eventual 4 cube/65cc racer build.@Red97 what top end are you thinking about on there?

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

Minor update:

I hunted down another 490. I figured I should put the 4910 jug on something. While I was putting it together I set it up with the HD12 to see what could be gained. Here are a few details of that swap.

First, you really have to shave off a lot from the boot flange and the air horn. Here’s the horn (mounted) beside a stock one. You can see I took 2/3 of the thickness away. You also have to stretch the holes that mount to the carb floor.

Then, the travel of the throttle vein hits the boot flange. I carved the flange a lot, but you could also cut off the circle mount on the vein.

The choke lever also needs a little work. You need to trim the rubber mount to allow the choke to fully open. Stock on the right. Slimmed on the left.

And the top cover just barely obstructs the end range of the lever, making it hard to fully engage the choke. A minor reshape fixes that.

Also, I swap the fuel and impulse lines. HD 12 needs some extra fuel line and less pulse, so just switcharoo.

I did some cuts up at my house and the saw is stronger up here than it was before down below. I think this mod may actually bring the 4910 up tight with 346. Maybe not quite beat it though.

Also, I think I bungled when I originally thinned the air horn. I think there was an uneven spot that allowed fines through. I tested both the mesh and the felt filters today. The mesh did seem to let a tiny amount of fines through, but not like what I found in the hybrid. I also couldn’t notice a difference in performance between the two filters.

I’m waiting on seals for the Hybrid, 4910 coil is installed and I modified the porting a bit. Hopefully there will be comparison videos soon.

I hunted down another 490. I figured I should put the 4910 jug on something. While I was putting it together I set it up with the HD12 to see what could be gained. Here are a few details of that swap.

First, you really have to shave off a lot from the boot flange and the air horn. Here’s the horn (mounted) beside a stock one. You can see I took 2/3 of the thickness away. You also have to stretch the holes that mount to the carb floor.

Then, the travel of the throttle vein hits the boot flange. I carved the flange a lot, but you could also cut off the circle mount on the vein.

The choke lever also needs a little work. You need to trim the rubber mount to allow the choke to fully open. Stock on the right. Slimmed on the left.

And the top cover just barely obstructs the end range of the lever, making it hard to fully engage the choke. A minor reshape fixes that.

Also, I swap the fuel and impulse lines. HD 12 needs some extra fuel line and less pulse, so just switcharoo.

I did some cuts up at my house and the saw is stronger up here than it was before down below. I think this mod may actually bring the 4910 up tight with 346. Maybe not quite beat it though.

Also, I think I bungled when I originally thinned the air horn. I think there was an uneven spot that allowed fines through. I tested both the mesh and the felt filters today. The mesh did seem to let a tiny amount of fines through, but not like what I found in the hybrid. I also couldn’t notice a difference in performance between the two filters.

I’m waiting on seals for the Hybrid, 4910 coil is installed and I modified the porting a bit. Hopefully there will be comparison videos soon.

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

So I had more trouble getting the HD12 to play nice than expected. First, the intakeboot kept collapsing out of my modified flange, so I had to go back to a stock flange and clearance it for the throttle travel. Then the butterfly was just barely hanging on the lip of the boot, so I had to go back in again and shave the edge of the butterfly. I just thinned it, no change in shape.

But I still had trouble. At my house it’s just too fat. With the H turned in all the way it still 4-strokes. The jet is just a tad too big. I need a jet from and HD-50 or maybe HD-18.

Luckily there is a lot more air down at the yard and it runs pretty well. Video uploading…

But I still had trouble. At my house it’s just too fat. With the H turned in all the way it still 4-strokes. The jet is just a tad too big. I need a jet from and HD-50 or maybe HD-18.

Luckily there is a lot more air down at the yard and it runs pretty well. Video uploading…

- Local time

- 1:30 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,517

- Reaction score

- 150,386

- Location

- East Jordan, MI

Solder it shut and re-drill smallerSo I had more trouble getting the HD12 to play nice than expected. First, the intakeboot kept collapsing out of my modified flange, so I had to go back to a stock flange and clearance it for the throttle travel. Then the butterfly was just barely hanging on the lip of the boot, so I had to go back in again and shave the edge of the butterfly. I just thinned it, no change in shape.

But I still had trouble. At my house it’s just too fat. With the H turned in all the way it still 4-strokes. The jet is just a tad too big. I need a jet from and HD-50 or maybe HD-18.

Luckily there is a lot more air down at the yard and it runs pretty well. Video uploading…

Dolkitafreak

Dolkita686

- Local time

- 1:30 PM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

Plug the bypass in the back of the nozzle. Plugging the hole that feeds the needle orifice makes the needle ineffective as that is now your restriction not the needle which allows tunability

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

I’m not sure what you mean by bypass. The nozzle has a .4mm hole on top, the H circuit will have a hole and there may be a third. Are you talking about the H circuit hole?Plug the bypass in the back of the nozzle.

I get what you’re saying, but this should work up to the point I want more fuel than .6 can supply. The needle on this carb is also questionable. The hole is offset in the needle seat. I don’t think it works very well. Prior to mods it was fat with the needle down tight. It does seem to adjust now, but I’ll have to fiddle a bit more to confirm. China carb…probably will end up modding the Walbro.Plugging the hole that feeds the needle orifice makes the needle ineffective as that is now your restriction not the needle which allows tunability

Dolkitafreak

Dolkita686

- Local time

- 1:30 PM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

I’m not sure what you mean by bypass. The nozzle has a .4mm hole on top, the H circuit will have a hole and there may be a third. Are you talking about the H circuit hole?

I get what you’re saying, but this should work up to the point I want more fuel than .6 can supply. The needle on this carb is also questionable. The hole is offset in the needle seat. I don’t think it works very well. Prior to mods it was fat with the needle down tight. It does seem to adjust now, but I’ll have to fiddle a bit more to confirm. China carb…probably will end up modding the Walbro.

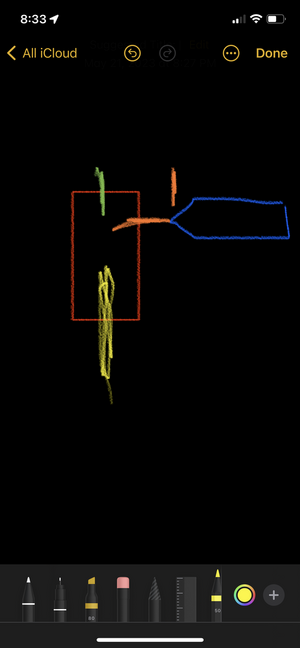

Red is nozzle. The green line is showing the bypass in the back of the nozzle, this ensures even with H needle turned too lean the saw stays a little rich, in some instances it’s wildly over sized (echo 590 comes to mind). Orange shows the hole that you filled and drilled, this feeds the path from the top of the needle into the nozzle, and all your restriction should be done from the point of the needle, not the hole up top as you lose some tuning ability. Yellow is the fuel from both the rear of the nozzle and the side of the nozzle all entering the motor.

Red is nozzle. The green line is showing the bypass in the back of the nozzle, this ensures even with H needle turned too lean the saw stays a little rich, in some instances it’s wildly over sized (echo 590 comes to mind). Orange shows the hole that you filled and drilled, this feeds the path from the top of the needle into the nozzle, and all your restriction should be done from the point of the needle, not the hole up top as you lose some tuning ability. Yellow is the fuel from both the rear of the nozzle and the side of the nozzle all entering the motor.So plugging the green allows you to more finely control the fuel with the needle, obviously if the hole in the side of the nozzle doesn’t align with the needle bore it’s gonna bypass some. I know I simplified this too much for @Ketchup but I hope it helps someone else who doesn’t have as much of a grasp.

- Local time

- 1:30 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,517

- Reaction score

- 150,386

- Location

- East Jordan, MI

As it is, there’s no fuel getting to the h screw. Like Ethan said. It will act like you have the screw all the way in.

Plug the brass hole and open the aluminum hole

Plug the brass hole and open the aluminum hole

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

Back to the hybrid. I got it all back together, new timing numbers. Started and tuned easy with the HD12. Took it up a tree and it was really great! And then…

I never liked that little nut that held the drum on. I guess I should have tightened it more. Hopefully only minor carnage. The nut has gone to the land of sawdust and landscape mulch forever.

I never liked that little nut that held the drum on. I guess I should have tightened it more. Hopefully only minor carnage. The nut has gone to the land of sawdust and landscape mulch forever.

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

The intake track on these little buggers is frustratingly small. The boot is a real constriction point, but I can’t find anything similar with a larger bore. The HD butterflies catch a bit in the air horn and on the stock boot. I gave them a little sharpen so they don’t stick.

I switched to this carb on the 4910. The bypass soldered C(hina)3M worked well, but would lean out when I tipped the saw up. This one may need a bit of solder as well. It’s pretty fat.

I switched to this carb on the 4910. The bypass soldered C(hina)3M worked well, but would lean out when I tipped the saw up. This one may need a bit of solder as well. It’s pretty fat.

- Local time

- 1:30 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,517

- Reaction score

- 150,386

- Location

- East Jordan, MI

A 2095 boot is really short and may work. Probably difficult to source though. Might be able to force a 359? 372? ring in there to spread your smaller boot open a little bit.The intake track on these little buggers is frustratingly small. The boot is a real constriction point, but I can’t find anything similar with a larger bore. The HD butterflies catch a bit in the air horn and on the stock boot. I gave them a little sharpen so they don’t stick.

View attachment 381153View attachment 381154

I switched to this carb on the 4910. The bypass soldered C(hina)3M worked well, but would lean out when I tipped the saw up. This one may need a bit of solder as well. It’s pretty fat.

Last edited:

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

I’m back to two running saws now. Unfortunately the 4910 still needs some carb tweaking but the Hybrid is fun! It revs high, has good torque, and aggressive throttle response. Currently running 20” 3/8 skip. It’s fast!

I made a comparison video but I feel like the 4910 needs leaned out more for a fair shake. Hopefully I can take a better video tomorrow.

I made a comparison video but I feel like the 4910 needs leaned out more for a fair shake. Hopefully I can take a better video tomorrow.

Ketchup

Epoxy member

- Local time

- 11:30 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,513

- Reaction score

- 8,444

- Location

- Colorado

I have a dead 2095! I’ll check it out. I tried the 359 ring. No dice.A 2095 boot is really short and may work. Probably difficult to source though. Might be able to force a 359? 372? ring in there to spread it open a little bit.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 51

- Views

- 8K